Save Time During SEM Sample Preparation: Target Prep

This article reviews how to improve process speed and efficiency for SEM sample preparation with a target preparation device before ion milling in the EM (electron microscopy) imaging workflow.

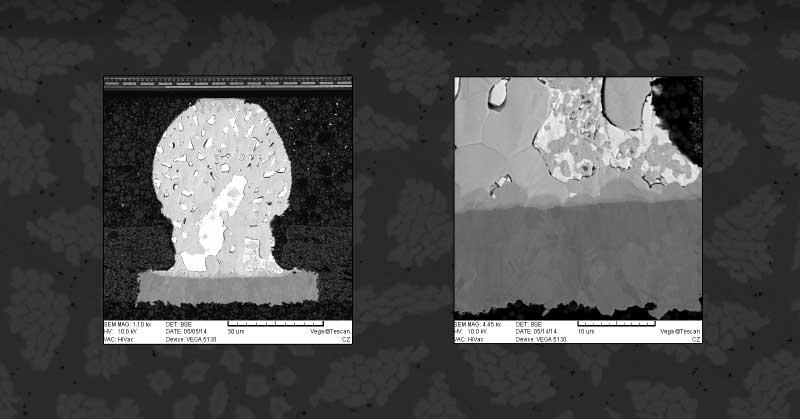

Today, ion beam milling is one of the most widely used methods for SEM sample preparation. Samples can be cross-sectioned to expose a desired area to inspect or polish for imaging techniques like EDS (Energy-dispersive X-ray spectroscopy) and EBSD (Electron backscatter diffraction).

The specimen surface is targeted with three high-energy argon-ion beams to remove very thin layers of material without the damage caused by mechanical methods.

Three Common Applications

- Milling down precisely to an embedded defect

- Surface preparation on specimens where there are many dissimilar materials - in this case, traditional methods will cause smearing on the surface, making it difficult to see complex grain structures

- Final polish to a pristine finish

SEM Sample Preparation is a Potentially Time-Consuming Process

The milling processing depends on the material type and the amount of material that needs to be removed. The process can take from a few minutes up to several hours.

This potentially lengthy process can impact lab productivity. Therefore, it is beneficial to have a complementary method for faster removal of unwanted material prior to using the ion mill to complete a “fine finish” on the surface of the specimen being prepared.

Adding a target preparation device to your workflow enables SEM sample preparation before the ion beam milling process.

Leica’s EM TXP Saves You Time During SEM Sample Preparation

Leica's EM TXP enables you to section, trim, grind, and polish materials before final ion beam milling. It accomplishes sample trim and polish quickly and accurately. As a result, you can effectively lower the capital and labor costs in your lab and increase productivity for your entire EM (electron microscopy) workflow.

Conventional sectioning and polishing require mounting a sample in a “puck” or other fixture before processing, whereas the EM TXP allows you to mount your sample on an SEM (scanning electron microscope) stub or AFM (atomic force microscopy) mount for processing.

The sample can then stay on these mounts during milling and go directly into the SEM (or sputter coater if needed). This saves time and processing steps that can cause damage.

Prepping a sample in the EM TXP is done under a microscope for the best accuracy. The EM TXP can advance saw blades and polishing pads in steps as fine as 0.5um. As a result, it is easy to target the area you want to image very accurately.

The EM TXP also enables you to polish samples automatically, setting an exact distance for material removal. You can tilt the sample while cutting and polishing, which allows you to remove excess material that would only add time to the milling process. This saves expense—you use fewer ion source hours to process more samples without wearing out your “guns”—which are consumable.

Conclusion

Adding a target preparation device like the Leica EM TXP helps save you time during SEM sample preparation and enables you to run your lab more efficiently.

If you have questions or need assistance with your sample preparation process, please use the form on this page to contact us. Or, give us a call at (408) 436-6336.

Get Application Support

Recent Posts