Recent Blogs

What Happens When Elves Discover Surface Metrology?

Recent Blogs What Happens When Elves Discover Surface Metrology? Candy

2025 Equipment Tax Benefits to Consider

Recent Blogs Equipment Tax Benefits for 2025! Is Now the

Reviving Legacy AFMs: How to Unlock New Capabilities

Recent Blogs Reviving Legacy AFMs: How to Unlock New Capabilities

Automotive Paint Layer Analysis with Microscopy & EDS | JH Technologies

Recent Blogs Automotive Paint Layer Analysis with Optical Microscopy, SEM,

What Is EBSD? A Guide to Electron Backscatter Diffraction in SEM

Recent Blogs A Guide to Electron Backscatter Diffraction (EBSD) Electron

EBSD Analysis and SEM Platform Considerations

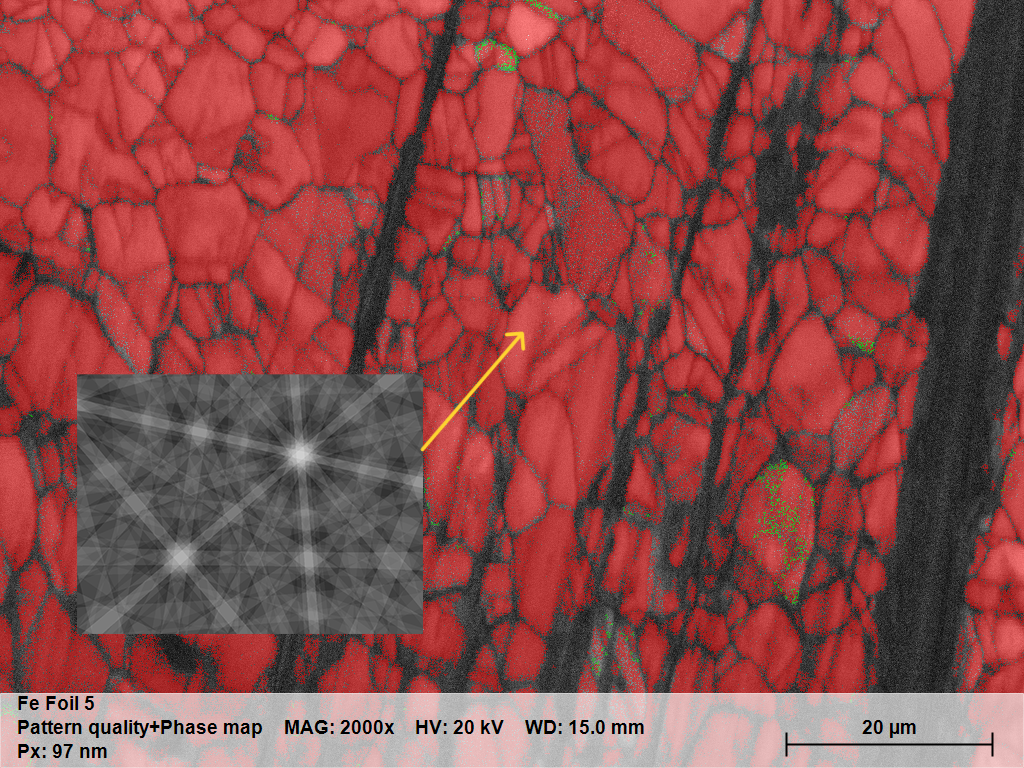

Electron Backscatter Diffraction (EBSD) is a powerful microstructural characterization technique increasingly integral to high-resolution SEM workflows. For researchers working in materials science, metallurgy, and applied physics, EBSD offers a robust pathway to extract crystallographic data directly from polished cross-sections and fractured samples.

The Role of EBSD in Crystallographic Characterization

EBSD enables spatially resolved mapping of grain orientation, phase distribution, strain gradients, and boundary character within polycrystalline materials. The technique involves detecting Kikuchi diffraction patterns generated by backscattered electrons at high tilt angles (typically ~70°) within an SEM. These patterns are indexed against crystallographic databases to generate orientation imaging maps (OIM), inverse pole figures, pole figures, and misorientation analyses.

Applications include:

– Recrystallization and grain growth kinetics

– Twin boundary quantification

– Phase transformation mapping

– Residual strain and local misorientation assessment

– Texture evolution in AM and thermomechanical processes

Core Instrumentation and Workflow Requirements

1. SEM Platform

EBSD can be integrated with both floor-standing and tabletop SEM platforms, though spatial resolution, detector geometry, and acquisition speed vary significantly:

– **Floor-standing SEMs** (e.g., CIQTEK SEM5000X, FEI Nova, Zeiss Merlin, JEOL IT800): Offer FEG sources, advanced detectors, and high-speed stage control, enabling spatial resolutions down to 20–50 nm with indexing speeds >1000 points/sec.

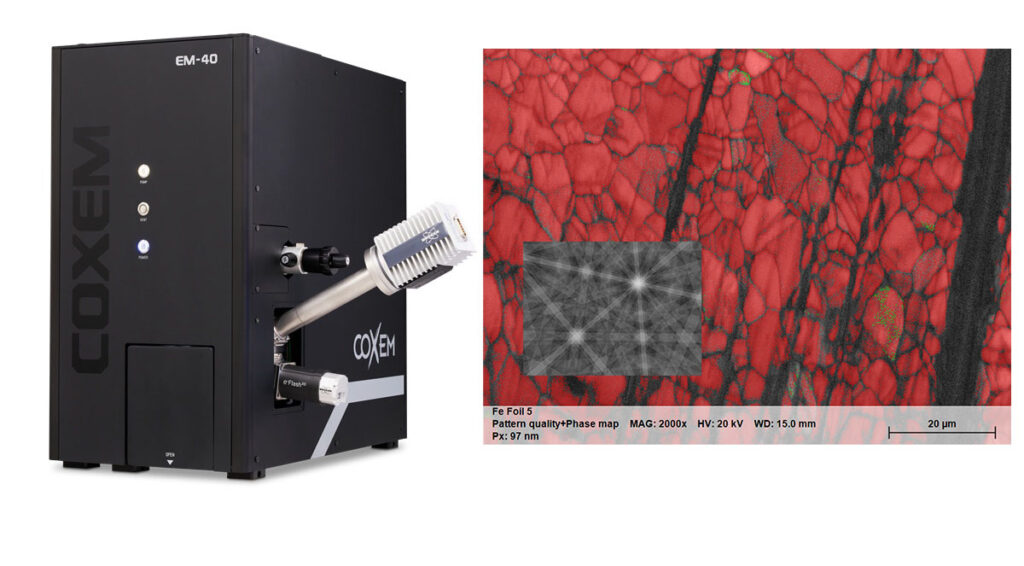

– **Tabletop SEMs** (e.g., Coxem EM-40 with Bruker e-Flash XS): Cost accessible and compact, suitable for basic orientation and phase mapping on coarse-grained or high-contrast systems. Indexing speeds from 50 – 200 points/second.

Coxem EM-40 with compacts EDSB – Photo courtesy of Coxem

Coxem EM-40 with compacts EDSB – Photo courtesy of Coxem

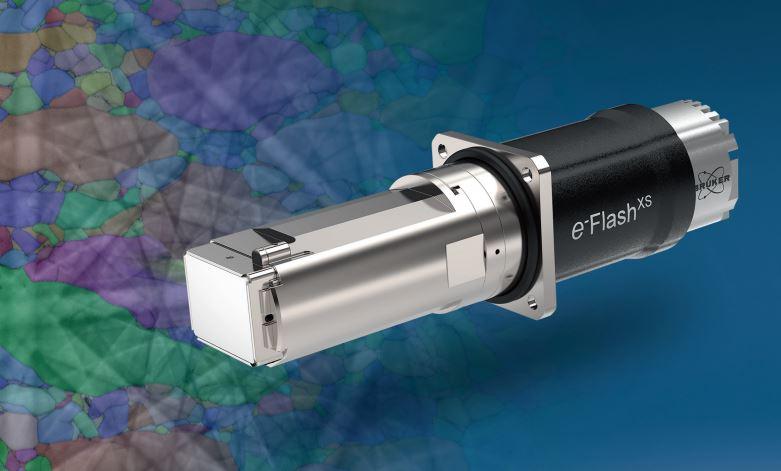

2. EBSD Detector and Optics

High-sensitivity EBSD detectors (CMOS or sCMOS-based) with optimized phosphor screens and fiber optics are required to resolve clear Kikuchi patterns. Detector placement, solid angle, and lens configuration impact pattern clarity and acquisition rates.

Compact EBSD detector for table-top SEM – Photo courtesy of Bruker

Compact EBSD detector for table-top SEM – Photo courtesy of Bruker

3. Indexing and Post-Processing

Software packages such as Bruker ESPRIT 2, Oxford AZtecCrystal, and EDAX OIM Analysis are used to index diffraction patterns and extract:

– Orientation Distribution Functions (ODFs)

– Grain boundary networks

– Phase maps

– Kernel Average Misorientation (KAM)

Advanced users benefit from scripting interfaces, batch automation, and integrated correlative imaging modules.

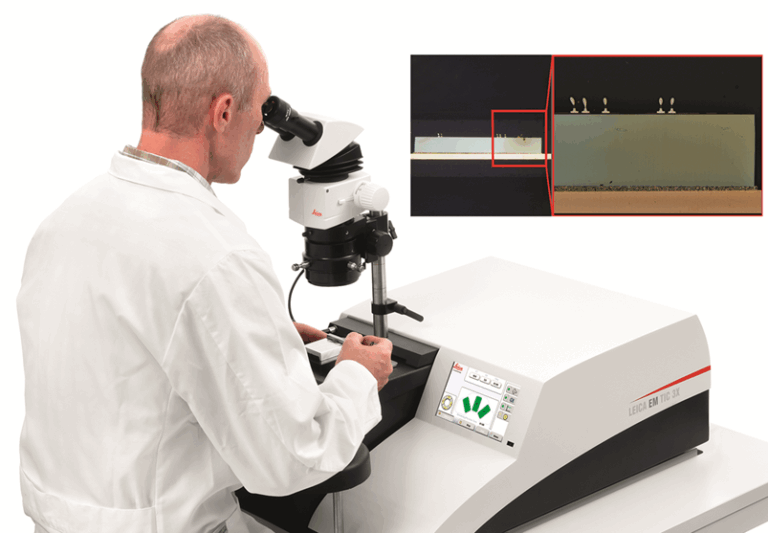

4. Sample Preparation Protocols

Sample preparation is critical. EBSD requires mirror-finish surfaces with minimal deformation. Ion beam polishing (e.g., Leica EM TIC 3X or JEOL IB-19520) is recommended for cross-sections, particularly in soft or multiphase systems. Avoiding contamination and surface oxidation is key.

Comparative Analysis: SEM Platforms for EBSD

Attribute | Floor-Standing SEM with EBSD | Tabletop SEM with EBSD |

Resolution (EBSD) | 20–50 nm (FEG SEMs) | 200–500 nm |

Indexing Speed | Up to 1500 points/sec | 50–200 points/sec |

Chamber Geometry | Optimized for multiple detectors and stage tilt | Limited—requires compact detector packages |

Pattern Quality | High SNR, suitable for advanced analysis | Acceptable for basic phase/orientation mapping |

Software Features | Full analytical suite, scripting, automation | Similar analytical suite with less advanced automation tools |

Sample Types | Broad: fine-grained, multiphase, deformed structures | Smaller sample size, less resolution |

Cost Range | $400K–$900K+ | $150K–$250K |

Footprint | Requires dedicated SEM suite | Fits on a bench, minimal infrastructure |

Conclusion

For researchers, lab leads, and materials scientists making procurement or workflow decisions, the choice between tabletop and floor-standing SEMs depends on resolution requirements, material systems under investigation, and budget constraints.

**Tabletop EBSD systems** offer streamlined, accessible analysis for basic materials characterization and teaching labs. **Floor-standing SEMs**, in contrast, support advanced EBSD workflows including deformation mapping, in-situ heating studies, and correlative FIB-EBSD analyses.

As EBSD technology continues to evolve, detector miniaturization and software automation are lowering the barrier to entry—enabling more labs to unlock crystallographic insights critical to material innovation.