Recent Blogs

What Happens When Elves Discover Surface Metrology?

Recent Blogs What Happens When Elves Discover Surface Metrology? Candy

2025 Equipment Tax Benefits to Consider

Recent Blogs Equipment Tax Benefits for 2025! Is Now the

Reviving Legacy AFMs: How to Unlock New Capabilities

Recent Blogs Reviving Legacy AFMs: How to Unlock New Capabilities

Automotive Paint Layer Analysis with Microscopy & EDS | JH Technologies

Recent Blogs Automotive Paint Layer Analysis with Optical Microscopy, SEM,

What Is EBSD? A Guide to Electron Backscatter Diffraction in SEM

Recent Blogs A Guide to Electron Backscatter Diffraction (EBSD) Electron

What Happens When Elves Discover Surface Metrology?

What Happens When You Scan a Candy Cane?

(And who does that anyway?)

Great question. Let’s start with the who—because that one’s easy.

Elves. Obviously.

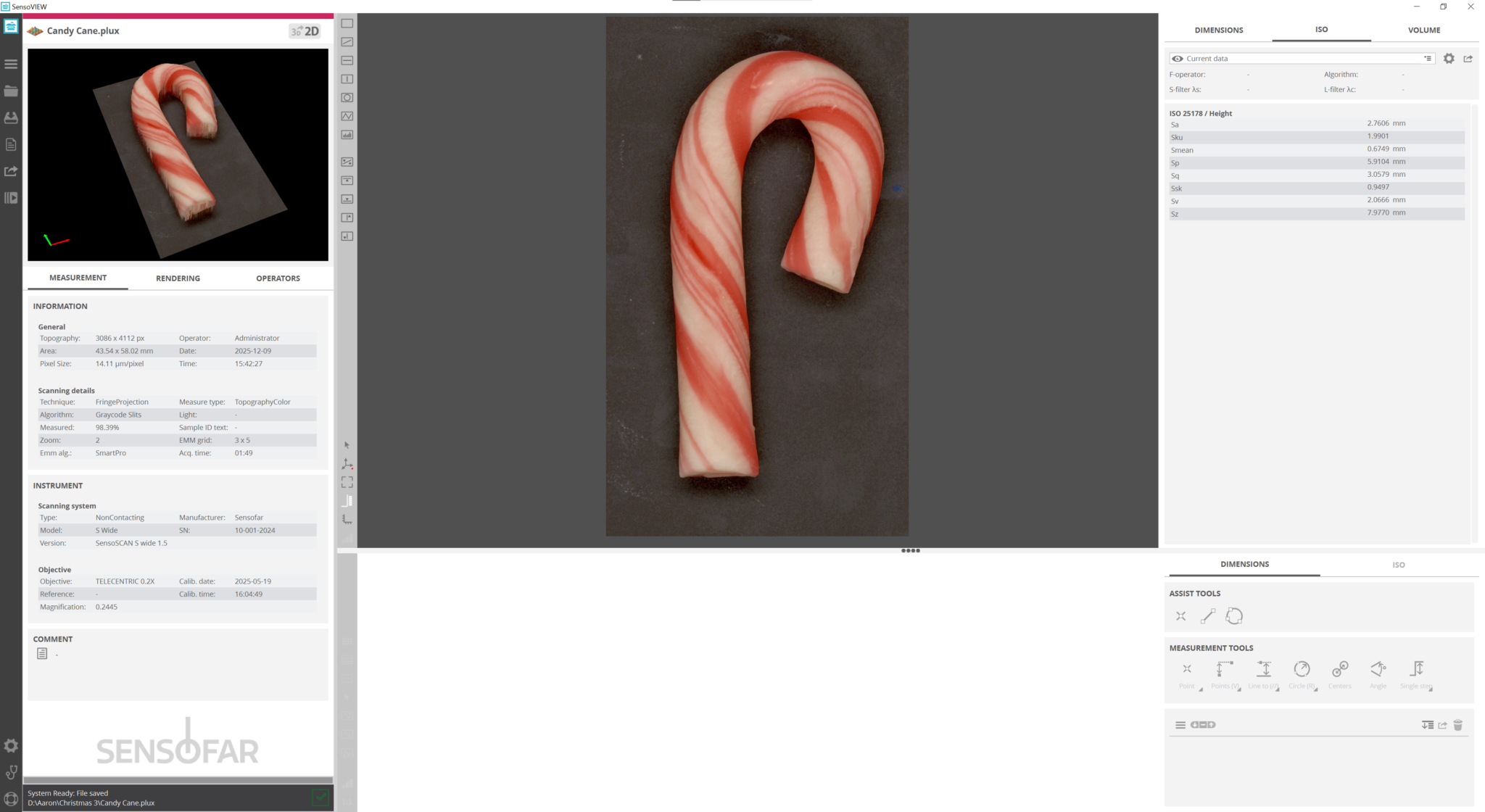

This holiday season, our applications lab discovered an untapped market for the Sensofar S wide: candy cane quality control at the North Pole. After all, when you’re producing millions of striped treats for the world, surface perfection matters.

So we did what any responsible group of metrology enthusiasts would do—we scanned a candy cane.

Using optical surface metrology, we analyzed a classic red-and-white striped candy cane to see whether those bold stripes translated into measurable height differences. Intuitively, you’d expect some variation between colors.

What we found surprised us.

Surface Profiling Results: A Surprisingly Smooth Candy Cane

Despite its dramatic stripes, the candy cane’s surface turned out to be remarkably smooth. The glossy outer coating creates a nearly uniform topography, which the S wide captured in precise 3D detail.

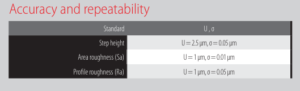

Based on the system’s specifications, we found no discernible height difference between the red and white stripes. In other words: visually bold, metrologically smooth.

This festive experiment confirms what we’ve long suspected—candy canes are a magical holiday treat, perfected down to the micron.

A Brief (and Totally Accurate) History of Candy Canes

Some historians—like Susan Benjamin of True Treats Historic Candy—suggest candy canes date back to a 17th-century German choirmaster who handed out sugar sticks to keep restless choirboys quiet. (Apparently preferable to “whacking them with a switch.”)

Charming story.

But let’s be honest—we all know candy canes are grown by elves at the North Pole. Case closed.

Why Use the Sensofar S Wide for Surface Profiling?

While candy canes may not be a typical application, this scan highlights exactly why the S wide excels:

- High-Resolution 3D Topography

- Capture intricate surface details quickly and accurately. Any elf can run a scan in less than one minute, allowing 100% quality control

- Large-Area, Non-Contact Measurement

- Ideal for curved, irregular, or delicate surfaces. Non-contact measurement helps maintain candy purity during the manufacturing process.

- Fast, Repeatable Results

- Perfect for high-throughput candy factories.

Whether you’re analyzing plastic toys, metal model trains, coatings on christmas ornaments — or festive sweets — the S Wide delivers reliable performance every elf depends on.

Conclusion: A Sweet Reminder of What Metrology Can Reveal

This holiday project proves that advanced optical metrology can turn even a candy cane into a fascinating topographic study. Sometimes the smoothest surfaces are hiding in plain sight.

That said, the Elf Quality Team had one final question:

Is it still that smooth at higher resolution?

Stay tuned—next month we’ll take a deeper dive into candy cane surface metrology using the Sensofar S neox.

Acknowledgment: Thanks to Our Applications Team and the short guys

Special thanks to our Applications Team and the crew at Santa’s candy factory for running the scans and confirming the quality of these tasty treats. Their creativity and expertise make fun, real-world demos like this possible.

Aaron Lowe applications engineer on-site at Elf factory Latitude 90 degrees North

Ready to See the Sensofar S Wide in Action?

Looking to explore surface profiling for your materials or components? We’re here to help you unwrap the full potential of optical metrology.

Connect with our team and request a quote today!