Recent Blogs

SEM: Low Vaccuum vs. High Vacuum Imaging – Webinar

Recent Blogs 5 Key Takeaways from Our Webinar: Low Vacuum

What Happens When Elves Discover Surface Metrology?

Recent Blogs What Happens When Elves Discover Surface Metrology? Candy

2025 Equipment Tax Benefits to Consider

Recent Blogs Equipment Tax Benefits for 2025! Is Now the

Reviving Legacy AFMs: How to Unlock New Capabilities

Recent Blogs Reviving Legacy AFMs: How to Unlock New Capabilities

Automotive Paint Layer Analysis with Microscopy & EDS | JH Technologies

Recent Blogs Automotive Paint Layer Analysis with Optical Microscopy, SEM,

Memory Device Cross-Sectioning [Learn from the JHA Team]

Producing Memory Device Cross-Sectiong Samples

Our newest JH Analytical Team member David is supporting and learning all of the functions in the lab.

What better way to learn than to produce some cross-section samples on your own!

We gave David a DRAM memory card and asked him to create cross-section samples to help our sales staff show Leica optics capabilities.

Below is a step-by-step pictorial view of our memory device cross-sectioning sample preparation process and final results.

A Day in the Analytical Lab

David and our intern Alex Lau created these samples in roughly one day while learning the ins-and-outs of processing electronic devices for analysis.

The samples came out great and you can see the resulting images below.

Different Imaging Methods Offer Different Results

We used different imaging methods to show the results you can expect. Each method has benefits, in addition to providing information and data.

The best method for memory device cross-sectioning and other analytical lab processes is the one that provides the data you need in the most cost-effective way.

As both a supplier and user of the tools used to generate the images below, we have the unique advantage of choosing the most appropriate tool for the job.

We invite you to visit our lab and see all that can be done to get you the answers you need. Complete the form on this page or give us a call at 408-436-6336 for assistance.

Memory Device Cross-Sectioning Process and Imaging Equipment

1. Entire DRAM Memory Board

1a) DRAM Memory Macro View

1b) DRAM Memory Single Lead Macro View

2) DRAM Memory Board After Initial Sectioning

2a) Completed Section of DRAM Memory Sample After Mounting and Polishing

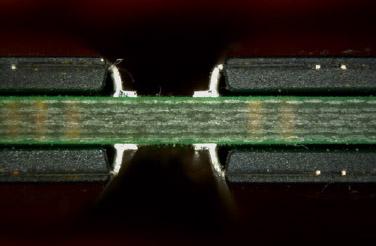

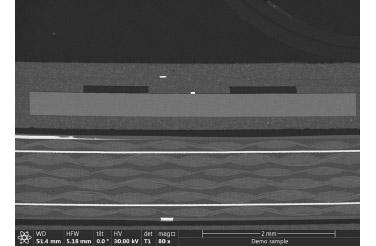

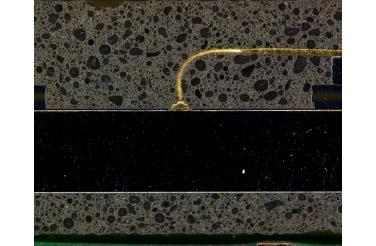

3) DRAM Memory Low Mag Cross-Section

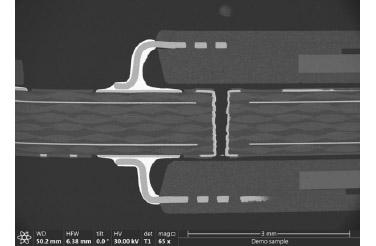

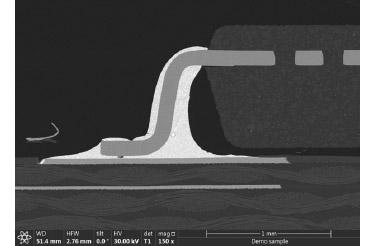

3a) DRAM Memory High Mag

3b) DRAM Memory Low Mag

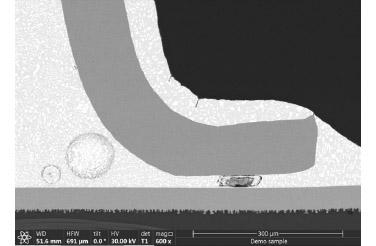

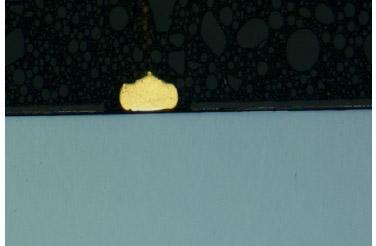

4) DRAM Memory Single Lead High Mag

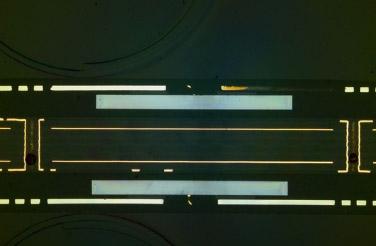

4a) DRAM Memory Single Lead Low Mag

4b) DRAM Memory Single Lead High Mag Showing Grain Structure

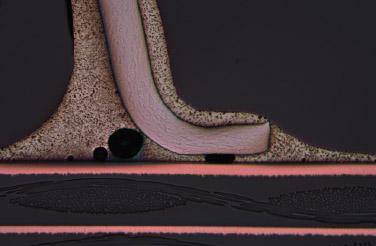

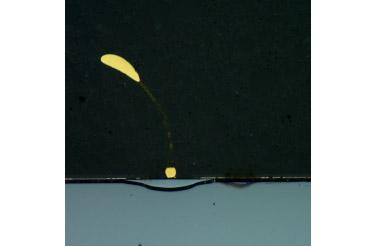

5) DRAM Memory Wire Bond Low Mag

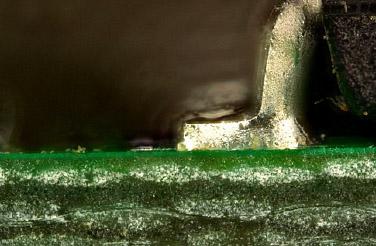

5a) DRAM Memory Wire Bond High Mag Darkfield Illumination

5b) DRAM Memory Wire Bond High Mag

5c) DRAM Memory Wire Bond High Mag EDF (Extended Depth of Field)