Recent Blogs

What Happens When Elves Discover Surface Metrology?

Recent Blogs What Happens When Elves Discover Surface Metrology? Candy

2025 Equipment Tax Benefits to Consider

Recent Blogs Equipment Tax Benefits for 2025! Is Now the

Reviving Legacy AFMs: How to Unlock New Capabilities

Recent Blogs Reviving Legacy AFMs: How to Unlock New Capabilities

Automotive Paint Layer Analysis with Microscopy & EDS | JH Technologies

Recent Blogs Automotive Paint Layer Analysis with Optical Microscopy, SEM,

What Is EBSD? A Guide to Electron Backscatter Diffraction in SEM

Recent Blogs A Guide to Electron Backscatter Diffraction (EBSD) Electron

Multi-Technique Characterization of Solder balls [Learn from the JHA Team]

Yifan Jiang – PhD, Applications Scientist – JH Technologies

Abstract

Solder balls are one of the most critical components in semiconductor packaging, and the metrology of detecting possible defects and integrity of the solder joints are of interest in recent years. In this article we present several characterization methods, including non-destructive and destructive methods to evaluate and characterize the solder balls’ size, porosity, microstructure and chemistry.

Keywords: solder ball, 2D Xray, 3D Xray, TXP, ion mill, optical microscopy, SEM, EDS, cross-section

Introduction

Ball Grid Array (BGA) packaging technology has been widely adopted in the semiconductor industry with its improved electrical and thermal performance compared to traditional packaging methods. With its short interconnects and high areal density of connection, BGA packaging reduces electrical impedance and thermal resistance, enabling a more efficient connection between components to PCBs. Possible defects including cracked solder joints, voids, contamination, delamination, or detachment can lead to failure of the entire electronic device. Thus, quality control of BGA components is critical to the performance and reliability of the electronic devices. [1-2]

Multiple inspection and failure analysis techniques, including electrical and mechanical testing, X-ray inspection, cross-sectional analysis are widely used to evaluate and find the root cause of failures. Since each technique has its own advantages and disadvantages, it is critical to understand the different techniques and what they are capable of.

In this article we present several methods of characterizing BGA components attached to PCBs, including non-destructive method of X-ray inspection, and destructive method of cross-sectional microscopy. We propose a complete workflow to locate the defect and conduct precision characterization on the defect in the solder ball.

Materials and Methods

Materials

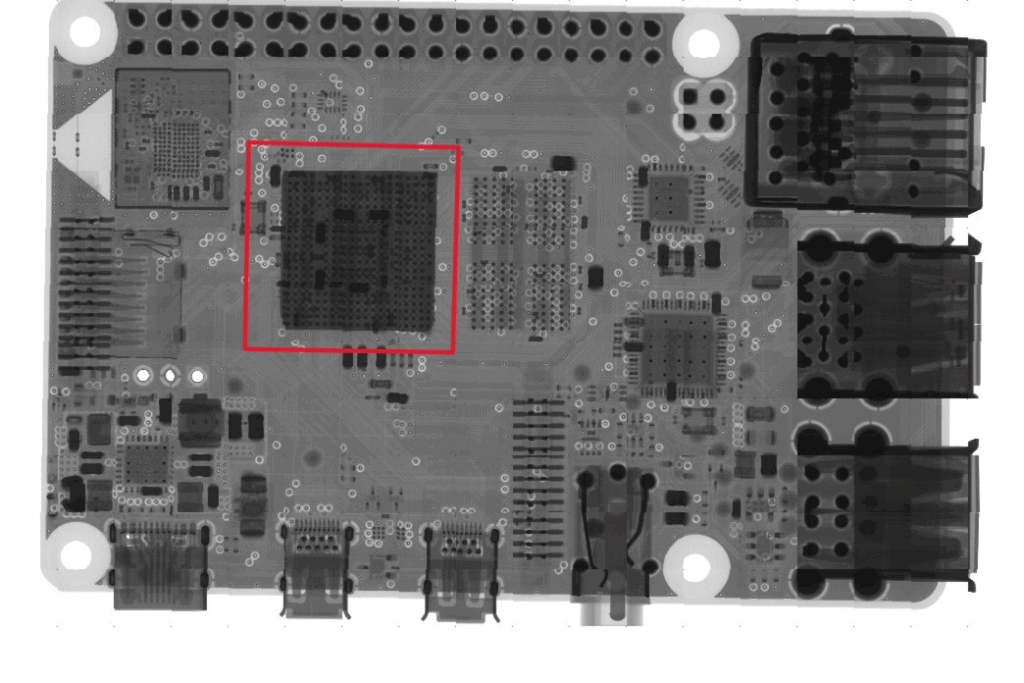

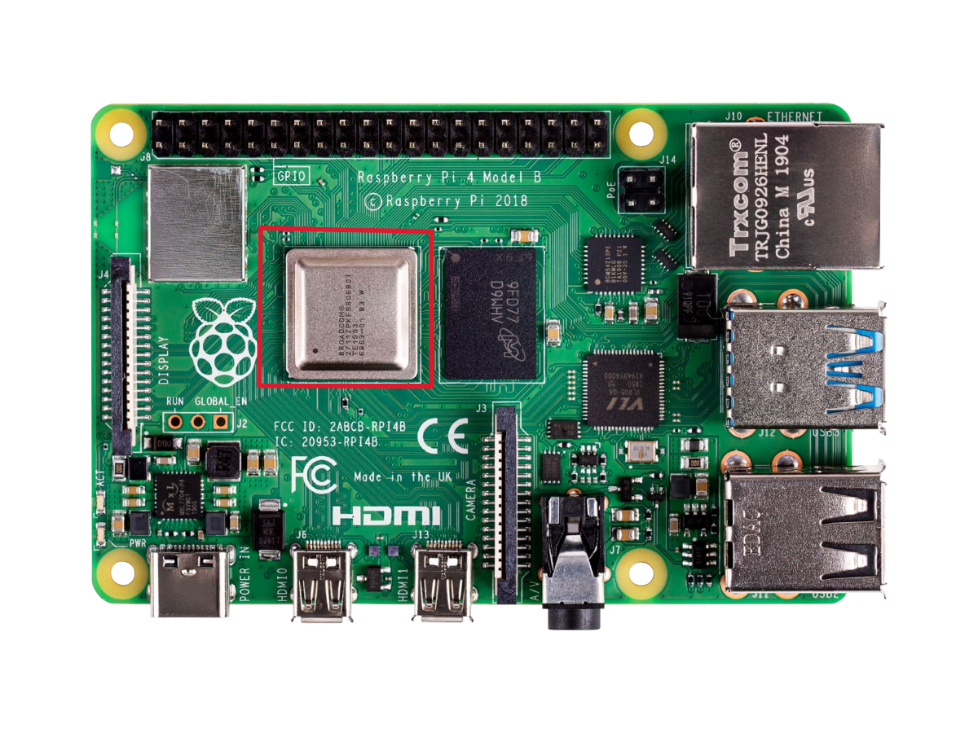

The sample of interest was a Broadcom BCM2711 Quad core Cortex-A72 (ARM v8) 64-bit SoC @ 1.8GHz SoC (System on Chip) from a Raspberry Pi 4 model B single board computer[3]. Figure 1 shows an overview picture of the product, with the SoC processor labeled.

X-ray Inspection

The entire board was characterized with XAVIS HSCAN-160-OCT X-ray system. The X-ray system contains a 5’’ flat panel detector and a powerful open-type X-ray tube, allowing the 1um focal spot to enable high resolution scans. The system allows both 2D and 3D scans. 2D scan creates an instant and direct view of the part through the X-ray, enabling quick inspection for defects. 3D scan provides more spatial information, creates a better visualization and allows more customizable interaction with the part and defect, despite the time that takes to create a 3D scan. Both 2D and 3D scans were conducted to check the orientation and location of each components on the SoC, as well as any visible defects. 2D scans provide an instantaneous view of the part, whereas it takes longer to complete the 3D scan.

Cross-section Preparation

The area of interest from the SoC was cross-sectioned and polished using a Leica EM TXP Cross-sectioning device. The system allowed precise sawing, milling, grinding and polishing the sample without removing it from the holder. The system was also equiped with a stereomicroscope, enabling real-time sample observation and checking during the sample prep. The sample was cut with a diamond saw blade and polished down to 0.5um with diamond lapping foil.

The sample was then ion-milled with Leica EM TIC 3X ion beam milling system with low energy to remove any surface contamination, surface tension, and create a smooth surface for microscopic characterization.

Microscopic Characterization

The sample was characterized optically under Leica DVM6 digital microscope. After the sample was coated with 4nm AuPd, the sample was characterized with CIQTEK 5000X FE-SEM and Bruker XFlash 7 EDS detector for a more detailed study regarding morphology, microstructure and chemical composition.

Results and Discussion

Non-destructive Characterization

Figure 2 shows a stitched 2D X-ray image showing the overview of the Raspberry Pi sample. The SoC processor is labeled in the figure. The overview images allows easy navigation on the product to find the feature of interest.

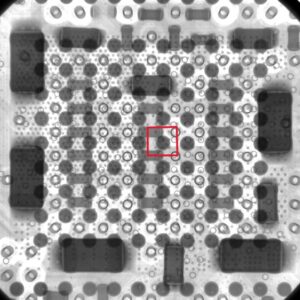

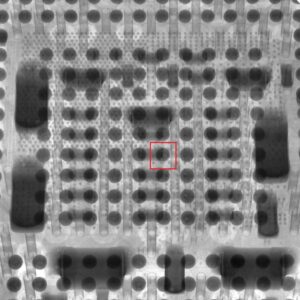

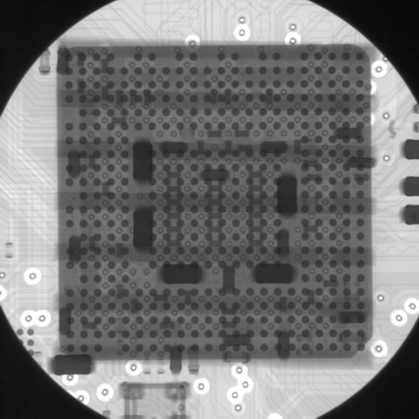

Figure 3 shows a low mag 2D X-ray image of the entire SoC processor. The darker the color, the harder the X-ray is able to penetrate, and that usually indicates a denser material. Figure 4 shows a higher magnification 2D image of the SoC center area. The sample was set at 0 deg tilt from the detector. Solder balls, capacitors, vias can be identified on the image. Some small voids can also be observed within the solder balls, but the vias overlapping in same XY position as the solder balls makes it challenging to locate the vias. Figure 5 shows the same area of the SoC center area at 40 degrees between the detector and the sample stage. 3D information such as the height of the via is revealed. Tilting the detector also allows better observation of the voids inside solder balls.

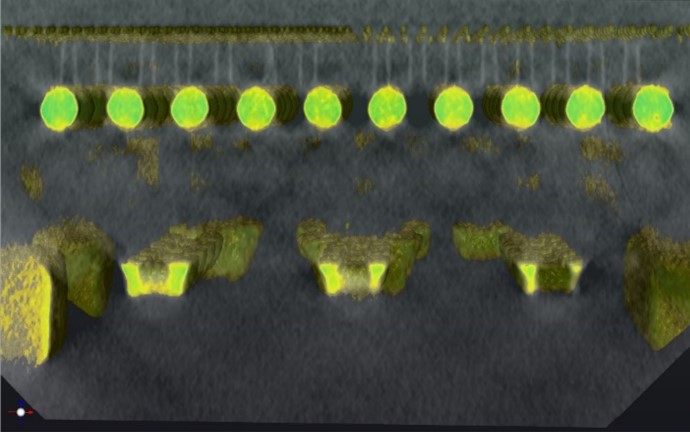

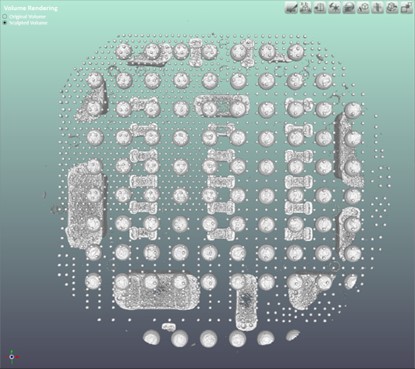

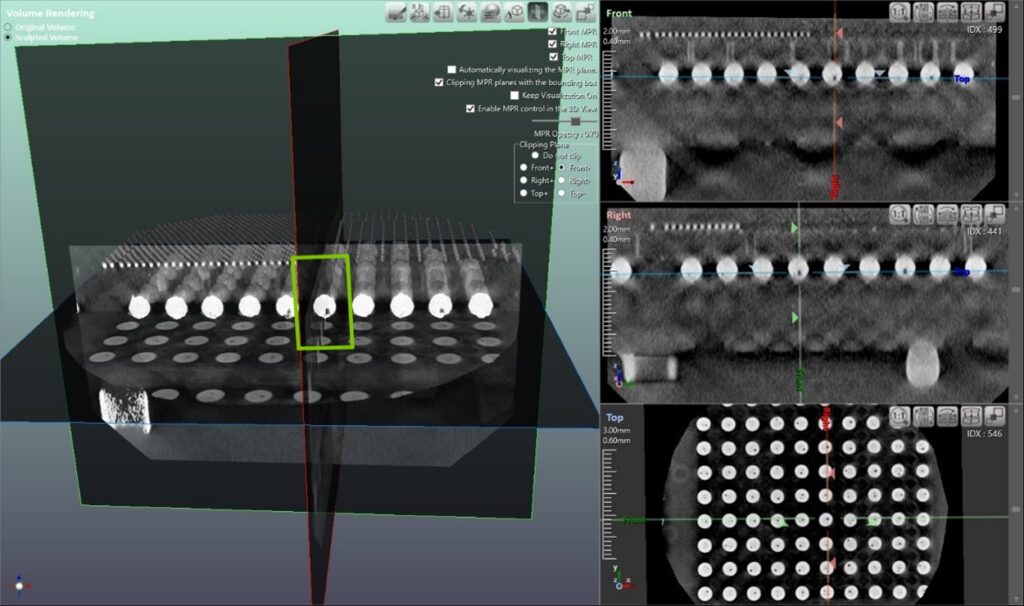

Despite the time that it takes to create the scan and reconstruction, 3D X-ray view provides more information in evaluating the relative size, volume and location of features in the sample. Figure 6 shows the 3D rendered top view image of the SoC. Features with low density, such as the vias, are not shown in the 3D view. Figure 7 shows the 3D rendered image as well as the 3 cross-sectional views of the region of interest. The center of the cursor focuses on the solder ball with the via that was identified in the 2D image. The volume percent and the position of the void can be obtained with 3D view. The volume percentage of the void is calcualted to be around 0.3% of the volume of the solder ball.

Destructive Characterization

Cross-sectional microscopy is a popular method to locate and characterize defects in a failed part. While X-ray technique has its challenge in identifying features with mixed density materials, microscopy provides a better visualization and better resolution on the part. This technique can be used to confirm the defects located with Xray and reveal more details on the part of interest.

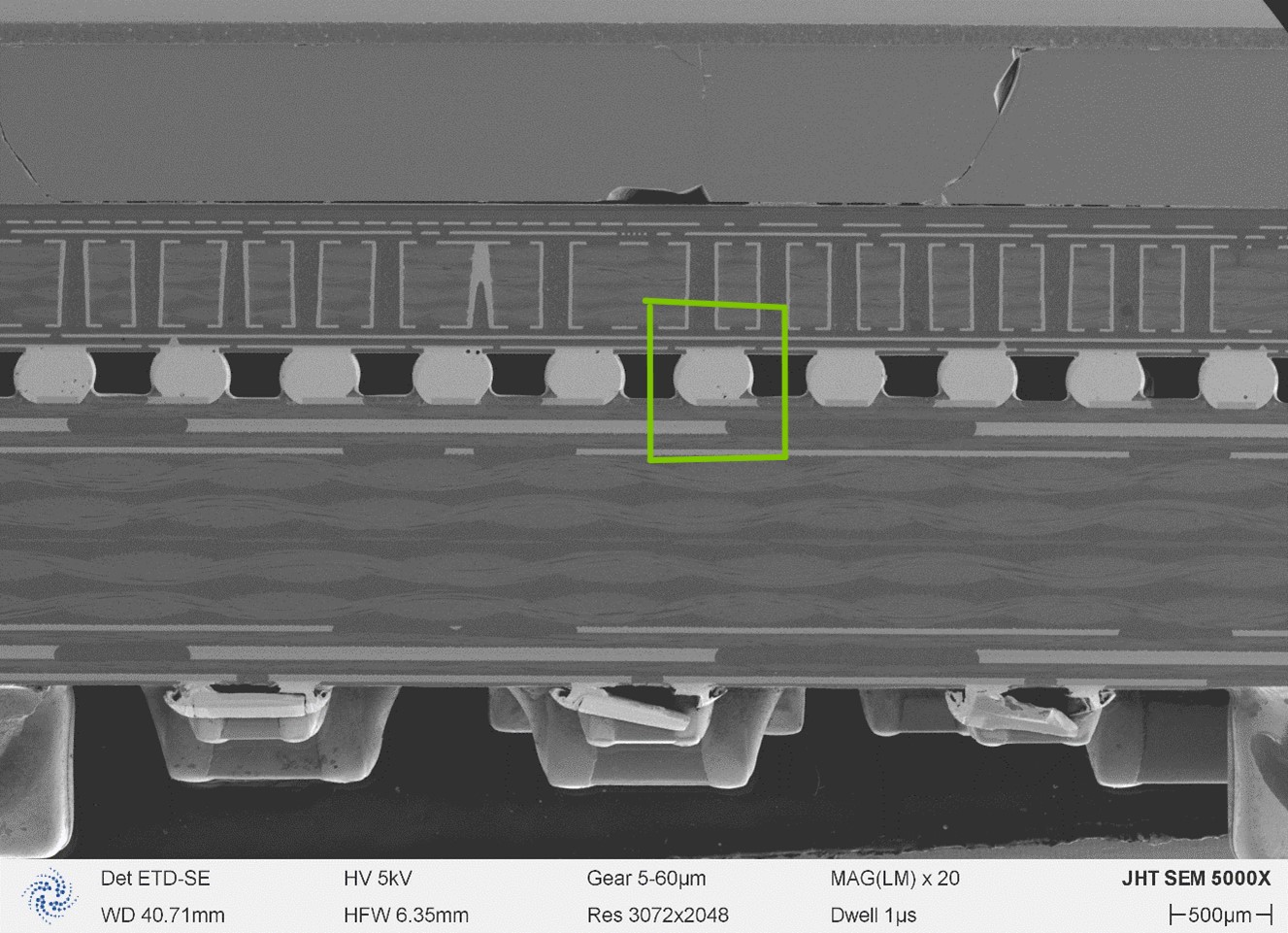

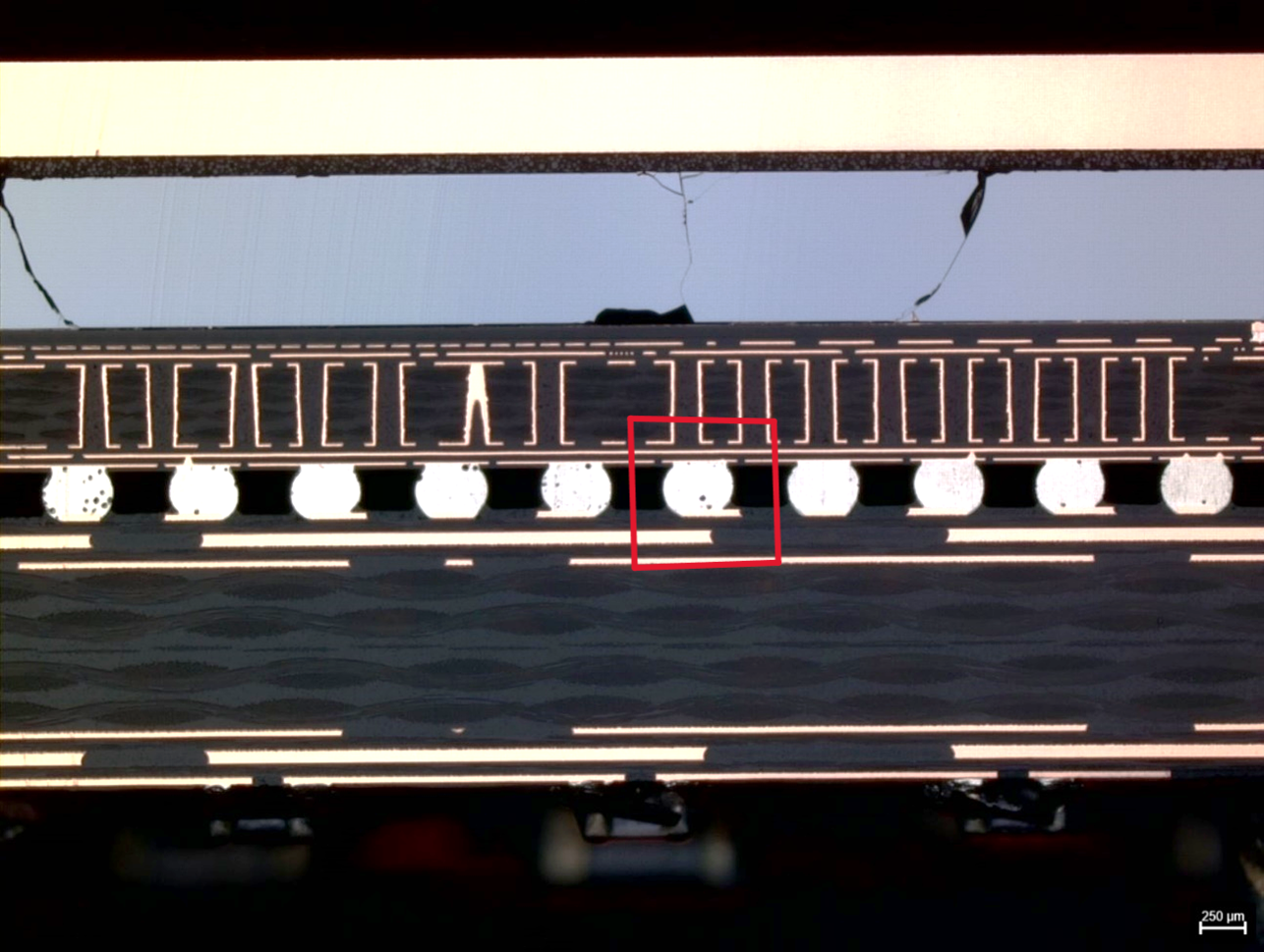

Figure 8 shows an overview of the SoC cross-section prepared with Leica TXP cross-sectioning device and Leica TIC 3X ion beam milling system. TXP was used to cut and polish into the row of solder balls highlighted from the Xray scan, and TIC 3X was used to create a good surface finish. Features including PCB, solder balls, interposer, IC, heat spreader are observed.

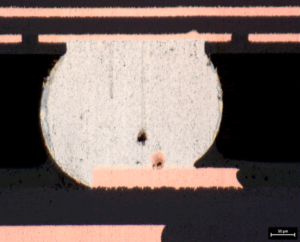

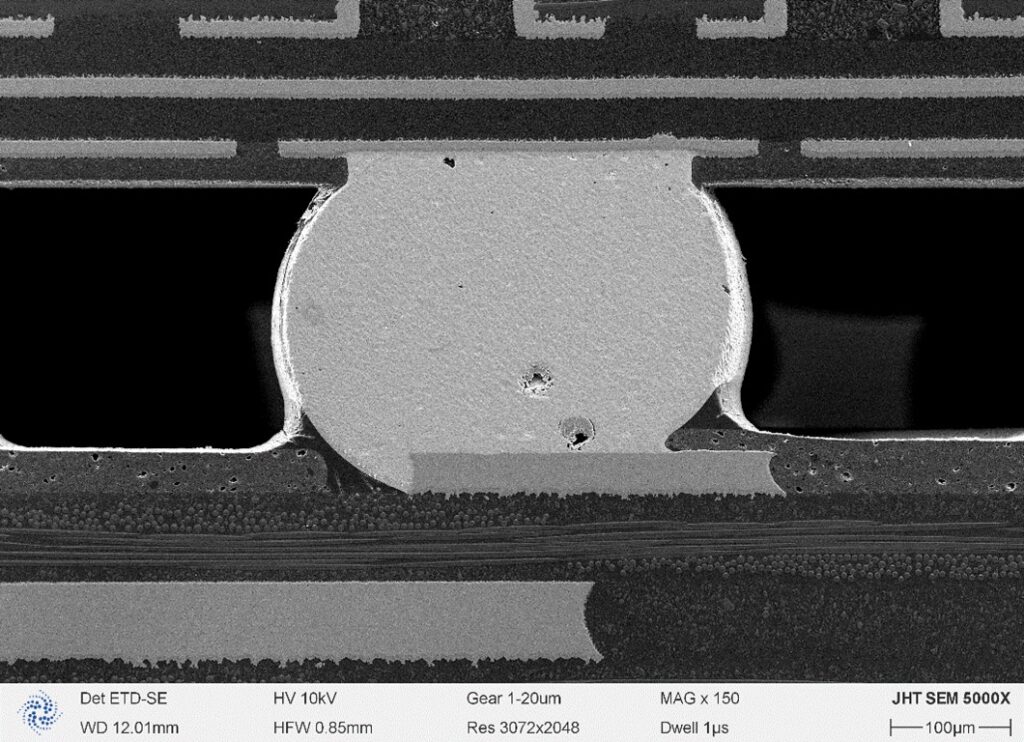

Figure 9 shows a closer look of the solder ball of interest, and compares the surface finish between TXP and TIC 3X. TXP allows precise cutting and polishing down to 0.5um motor steps, with in-situ viewing capabilities through a stereomicroscope. The sample was polished to 0.5um diamond pad. As seen in Figure 9(a), TXP polishing creates a surface finish with very few scratches, allowing the observation of the void inside the solder ball. Figure 9(b) shows the solder ball cross-section after polishing with TIC 3X. The ion milling process not only removes the scratches from the previous polishing step, but also reveals the microstructure in the solder ball. Some smaller voids can also be observed in the optical microscope.

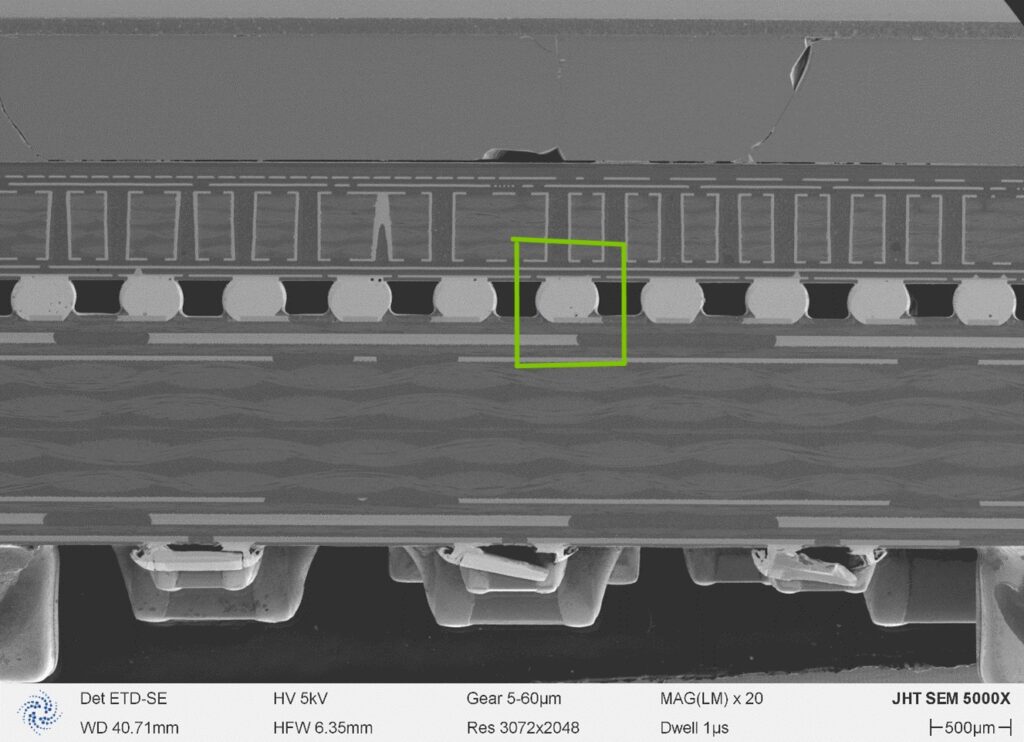

Figure 10 shows the overview cross-sectional image of the same sample. The sample was coated with 4nm Au-Pd and imaged with CIQTEK 5000X FE-SEM. Similar field of view as Figure 8 at low magnification can be obtained with the SEM. Due to better depth of field of SEM compared to optical microscope, information below the cross-section surface such as capacitors on the PCB can be observed.

Figure 11 are SEM images of the solder balls at higher magnification and using h different detectors (a) Secondary electron detector (SE) (b) Backscattered electron detector (BSE), (c) Mixed detector of both SE and BSE

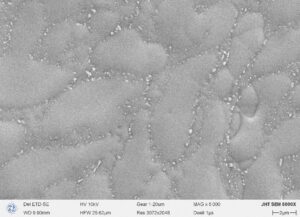

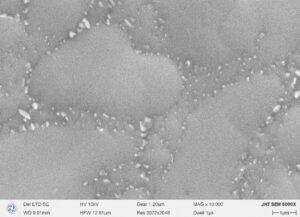

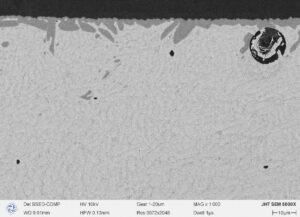

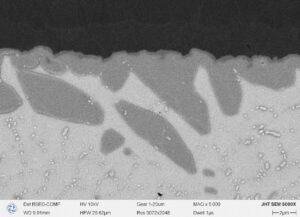

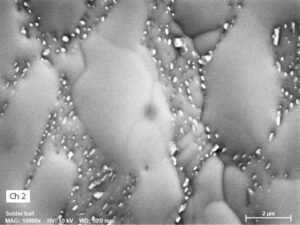

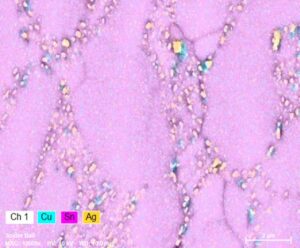

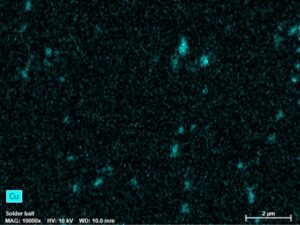

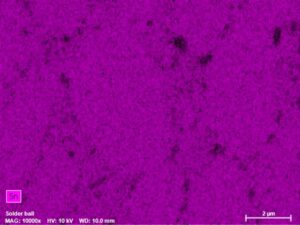

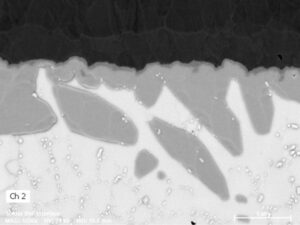

Besides the overview of the solder balls, SEM can also review microscopic information of the solder ball. The following pictures were taken on a different solder ball from this cross-sectional sample. Figure 12(a) and Figure 12(b) show some high magnification images of the microstructure on the solder ball cross-sections. Grains of different orientations are observed with the SE images, and small submicron particles are observed along grain boundaries. Figure 13(a) and Figure 13(b). BSE images show the interface between the solder ball and the Cu pad. Different contrasts of materials are observed at the interface.

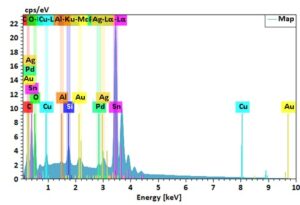

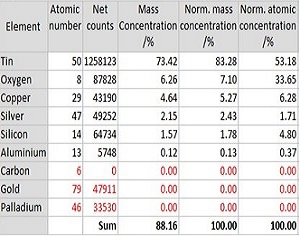

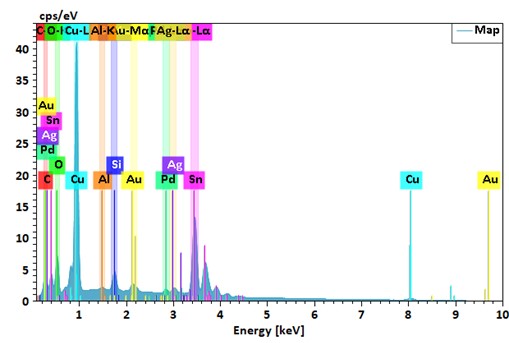

To understand the chemical composition of the grain boundary particles and interfacial material composition, EDS (Energy Dispersive Spectroscopy) is performed. With Bruker 100mm Flash 7 EDS detector, chemical composition of small particles can be identified and mapped out.

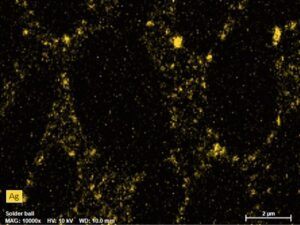

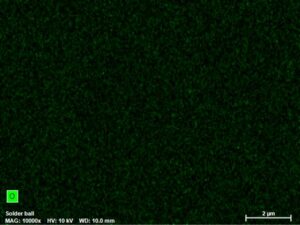

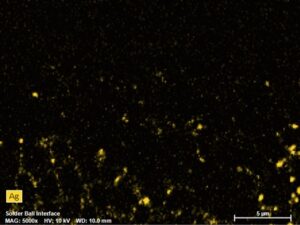

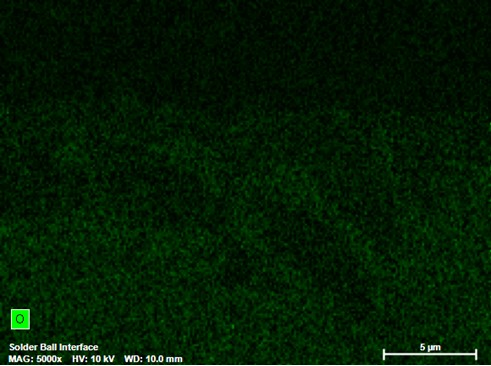

Figure 14 shows an EDS mapping scan at 10000X on the grains in the center of the solder ball. Cu, Sn, Ag and a small amount of O are observed in the solder ball. Sn is identified as the matrix of the solder material. Ag is observed distributed around the grain boundaries, and the small particles along the grain are also identified as Ag. Some Cu particles are also observed along the grain boundaries. These small particles can be precipitation from the solder ball reflow and cooling process.

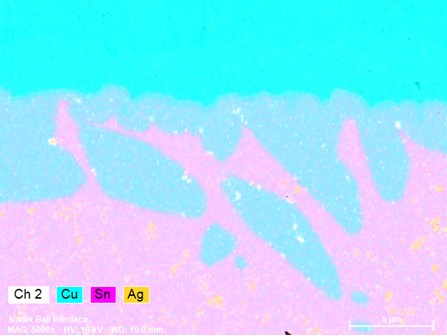

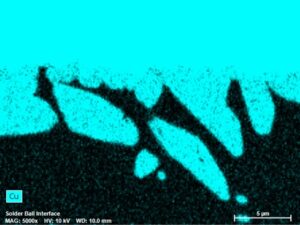

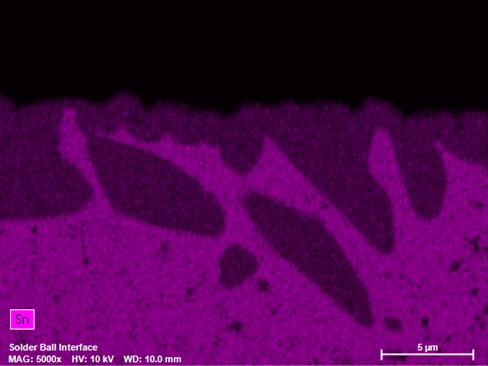

Figure 15 shows the EDS mapping of the interface area between the solder ball and the Cu pad. Similar to the previous EDS analysis, Sn, Ag, and small amount of Cu and O are observed inside the solder ball. Ag is mainly observed around the grain boundaries inside the solder ball and small particles are observed along the grain boundaries. A mixture Sn and Ag is observed at the interfacial island area that shows a different contrast compared to the Cu pad and the body of the solder ball. Some oxygen gradient is observed at the interface, with higher content of O observed within the solder ball body compared to the Cu-rich areas.

To sum up this section, microscopic analysis on the cross-section can provide detailed information regarding size, microstructure, morphology and chemical composition of the component of interest. This information is essential for quality control, failure analysis and process improvement.

Comparison

In the previous sections 3 different characterization methods are presented to show how we can image the cross-section of the SoC, with different strengths and limitations. Figure 16 shows a quick comparison of the same view obtained under 3D CT Xray, optical microscopy and SEM.

3D Xray:

- Strength: 3D Xray creates non-destructive imaging on the part to view the internal structure of the sample, and allows interaction to find the feature of interest.

- Limitation: Micron-level resolution is lower compared to advanced optical microscopic and SEM imaging. Low density materials are challenging to observe when there is a mixture of materials.

Optical Microscopy:

- Strength: Optical microscopy requires little sample prep to mount and view the sample. Sub-micron resolution can be achieved at high magnifications. If the sample is prepared well, microstructure can be observed.

- Limitation: It is a destructive characterization method. Depth of view is relatively shallow at high magnifications. It is considered a surface technique for non-transparent materials, and only one cross-section can be imaged at a time.

SEM:

- Strength: SEM can reach sub-nanometer resolution, allowing detailed study on microstructure, morphology, and chemical composition with different detectors. Chemical analysis can be achieved with additional EDS detector.

- Limitation: It is a destructive characterization method. Some sample prep such as conductive coating is needed for good imaging. It is considered a surface technique, and only one cross-section can be imaged at a time.

Since these techniques complement each other, a proposed work flow for an unknown defect is to:

- Investigate the sample with Xray to locate the defect

- Prepare precise cross-section using different cutting and polishing techniques, with timely optical microscopy to confirm the progress and quality of work.

- Characterize microstructure, morphology or chemical composition using SEM

Conclusion

Both non-destructive 2D and 3D X-ray scans, and destructive cross-sectional microscopy are conducted on the SoC processor. With different focuses of each technique, a work flow is proposed to start with the non-destructive method to locate the feature of interest, and followed by characterizing the feature of interest with SEM or optical microscope after preparing the cross-section.

Reference

1. J.J. Liu, H. Berg, Y. Wen, S. Mulgaonker, R. Bowlby, A. Mawer, Plastic ball grid array (PBGA) overview, Mater. Chem. Phys. 40 (4) (1995) 236–244, https://doi. org/10.1016/0254-0584(95)80004-2

2. M.A. Razzaq, M. Meilunas, X. A. Cao, J. Wilcox, A. Ramini, Effects of solder solidification temperature on residual stress distribution and failure location in BGA solder joints, Microelectronics Reliability, 166, (2025), 115609

3. https://www.raspberrypi.com/products/raspberry-pi-4-model-b/specifications/

4. https://datacapturecontrol.com/articles/io-devices/single-board-computers/raspberry-pi-4b