Ion Milling Equipment

Broad beam ion milling machines for superior SEM Sample Preparation

Advanced Ion Beam Milling—The Coxem CP-8000+

Complete System Special Promotion

A complete ion milling system with flat milling capability for less than $99K.

Fast—etching rate of 700 μm per hour (based on Si, 8 kV)

- Efficient—save and load frequently used recipes

- Automated—step-by-step recipes with an automatic execution function

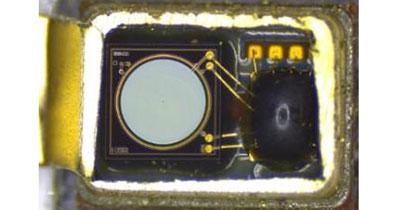

- Fast and easy sample loading with the smart sample holder and built-in digital microscope for ion beam sample alignment

- Real-time status of ion beam and etching through chamber camera

- Intuitive GUI with easy touch screen

- Minimized thermal damage with the auto on/off ion beam function

- Noise, vibration, oil-free operation

- Large area plane etching capability with flat milling function

Affordable Ion Milling Equipment

Ion Milling Overview

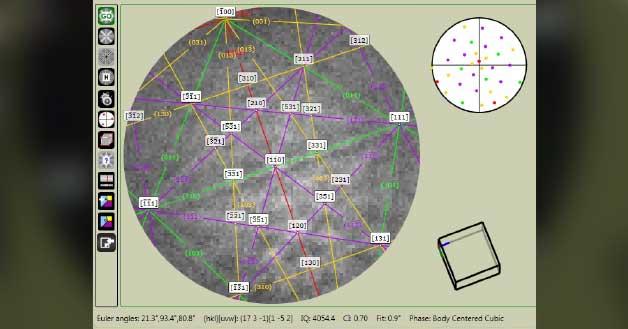

Ion milling is a sample preparation technique that uses a beam of high-energy ions to remove material from a sample surface. Ion milling is widely used to prepare samples for SEM analysis, especially for EDS and EBSD.

What are the two types of broad beam ion mills?

There are two main ion milling techniques used today in sample preparation. Dual beam, also called Focused Ion Beam (FIB) milling, and large area ion beam milling (Broad Beam Ion Milling).

We use a broad beam ion milling machine to prepare samples for analysis in our lab.

Ion milling can be used to prepare a wide variety of samples, including electronics, metals, ceramics, polymers, and composites.

Benefits of Ion Milling for Sample Preparation

Because ion milling is a non-contact technique, it does not damage the sample surface and can be used to polish delicate and soft materials that would be damaged using mechanical polishing methods. Materials like polymers that cannot be mechanically polished due to ease of damage or cannot be exposed to heat can be polished using a cryogenic stage on the ion mill.

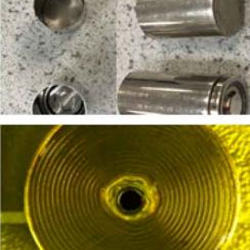

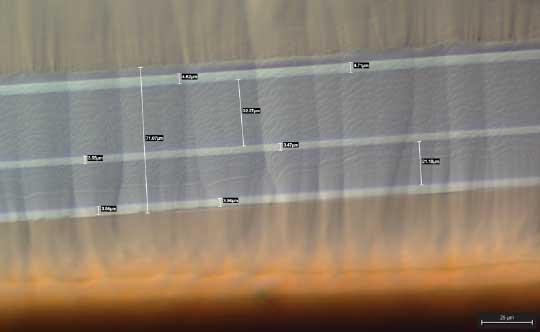

Samples mounted in ‘pucks” can be “flat milled” to remove surface damage from mechanical polishing and to prepare samples for EBSD.

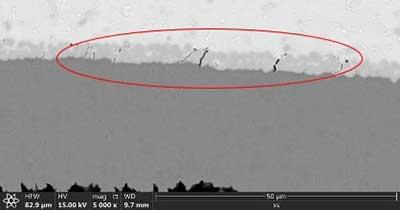

Ion milling also works very well for soft materials that tend to smear or get inclusions when polished mechanically. This is highlighted when polishing electronic interfaces that have soft and hard materials right next to each other. Ion milling will remove smearing caused by regular polishing. This allows for better imaging, measurements, and elemental analysis.

Ion Milling Equipment

The CP-8000+ is an advanced cross-section polisher that etches a sample cross section using an argon ion beam. The ion milling process avoids physical deformation and structural damage, and does not require complicated chemical processes. In addition, the system simplifies cross-sectional analysis of the sample by processing large areas from tens of um to several mm.

The Leica EM TIC 3X is a triple ion beam milling system that enables the production of cross-sections and planed surfaces for scanning electron microscopy (SEM), microstructure analysis*, and AFM investigations.

*Microstructure analyses include energy dispersive X-ray spectroscopy (EDS), wavelength-dispersive X-ray spectroscopy (WDS), auger, and electron backscatter diffraction (EBSD).

Leica TXP

The Leica EM TXP is a target preparation device for milling, sawing, grinding, and polishing samples prior to examination by SEM, TEM, and LM techniques.

Ion Milling Videos

Ion Milling Equipment—Request a Quote

Ion Milling—Related Equipment and Accessories

Ion Milling Flat Stage for Coxem CP-8000+ Ion Mill

Designed for plabe etching of large surfaces

Cooling Stage TIC 3X

The cooling stage provides very low temperature processing for applications using polmers, rubber, food, cosmetic , pharmaceuticals, or heat sensitive metals

VCT Vacuum Transfer Docking Station

A solution for environmentally sensitive samples