Ion Milling Equipment for SEM & EBSD Sample Preparation

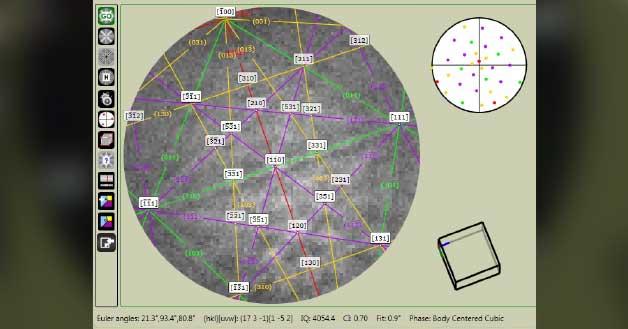

JH Technologies offers a range of high end to affordable ion milling equipment designed to perform precision sample preparation for Scanning Electron Microscopy (SEM), Energy Dispersive X-ray Spectroscopy (EDS), Electron Backscatter Diffraction (EBSD), and Atomic Force Microscopy (AFM).

We supply broad beam and cross-section ion milling machines from leading manufacturers including Leica Microsystems and Coxem, with advanced features to support high-quality imaging and analysis.

Contact our team below if you need help understanding which system is right for you.

The Affordable Coxem CP-8000+ Ion Beam Cross-Section Polisher

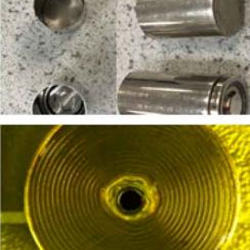

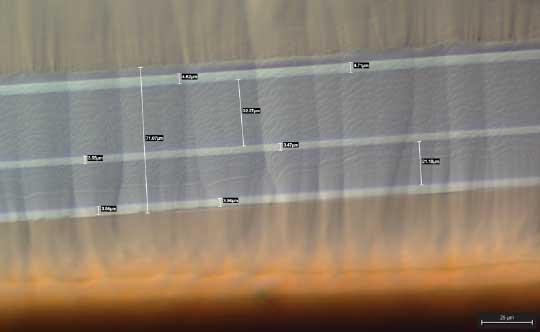

The CP-8000+ is a high-performance argon ion beam polisher designed for fast, damage-free sample cross-sectioning. This advanced system simplifies SEM sample preparation by enabling large-area etching without mechanical deformation or chemical processing.

This ion milling machine is ideal for SEM sample prep for cross-section analysis, flat milling for EBSD preparation, polishing soft or heat-sensitive materials like polymers and composites, and electronics and microstructure analysis.

- Argon ion beam system with flat milling capability

- High-speed etching rate: 700 μm per hour (based on Si, 8 kV)

- Smart sample holder with integrated digital microscope

- Real-time chamber camera and beam monitoring

- Touchscreen interface with automated recipe execution

- Minimized thermal damage with auto on/off beam function

- Oil-free, low noise, vibration-free operation

Affordable Ion Milling Equipment

Leica EM TIC 3X Tripe Ion Beam Milling System

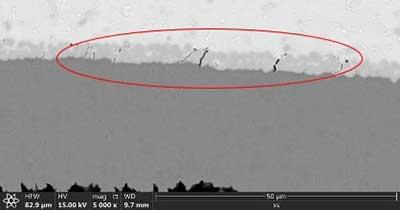

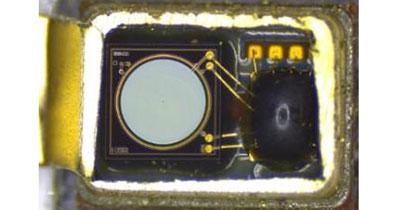

The Leica EM TIC 3X is a versatile triple ion beam milling system designed for high-precision cross-sectioning and planar surface preparation. It supports a wide range of microscopy techniques and provides consistent, artifact-free surfaces ideal for analytical imaging.

This ion beam milling system is ideal for sample prep for SEM, EDS, Wavelength-Dispersive X-ray Spectroscopy (WDS), Auger, and EBSD, metals, ceramics, polymers, and composites, and high-resolution microstructure and failure analysis.

Leica EM TXP Target Preparation System

The Leica EM TXP is a compact target preparation device that combines milling, sawing, grinding, and polishing capabilities in one system.

This system is ideal for preparing small or delicate specimens prior to imaging with SEM, TEM, or LM, delicate or site-specific sample targeting, research and QA labs requiring precise manual prep.

Ion Milling Equipment—Request a Quote

Ion Milling Accessories & Add-Ons

Ion Milling Flat Stage for Coxem CP-8000+

Engineered for large-area planar etching, the flat stage enables uniform milling across broad sample surfaces. Ideal for EBSD prep, this accessory improves sample flatness and consistency, particularly on delicate or irregular specimens.

Cooling Stage for Leica EM TIC 3X

This advanced cooling stage enables low-temperature processing for heat-sensitive or soft materials. It is essential for applications involving polymers, biological samples, pharmaceuticals, and other temperature-sensitive materials that require damage-free preparation.

VCT Vacuum Transfer Docking Station

Designed for environmentally sensitive samples, this vacuum transfer station allows seamless movement of specimens between instruments without exposure to air. It’s an essential tool for preserving surface integrity in high-vacuum and inert gas workflows.