Recent Blogs

What Happens When Elves Discover Surface Metrology?

Recent Blogs What Happens When Elves Discover Surface Metrology? Candy

2025 Equipment Tax Benefits to Consider

Recent Blogs Equipment Tax Benefits for 2025! Is Now the

Reviving Legacy AFMs: How to Unlock New Capabilities

Recent Blogs Reviving Legacy AFMs: How to Unlock New Capabilities

Automotive Paint Layer Analysis with Microscopy & EDS | JH Technologies

Recent Blogs Automotive Paint Layer Analysis with Optical Microscopy, SEM,

What Is EBSD? A Guide to Electron Backscatter Diffraction in SEM

Recent Blogs A Guide to Electron Backscatter Diffraction (EBSD) Electron

Automotive Paint Layer Analysis with Optical Microscopy, SEM, and EDS

Author: Yi Zhang, PhD. JH Technologies Application Scientist

Abstract

Automotive paint typically consists of multiple layers designed to provide corrosion resistance, color, and a durable glossy finish. In this study, we used optical microscopy, scanning electron microscopy (SEM), and energy-dispersive X-ray spectroscopy (EDS) to characterize the microstructure and elemental composition of the paint layers on a car body.

Materials and Methods: Automotive Paint Sample Preparation

A metal specimen with paint coatings on both sides was sectioned from the vehicle body and mounted in epoxy. The cross-section was ground and polished using a Buehler AutoMet 250 Pro grinder–polisher and mounted in an epoxy puck preparing it for subsequent analysis.

Characterization Methods: Optical Microscopy, SEM, and EDS

- Optical Microscopy: A Leica DMI8 optical microscope was used for initial microstructural observation.

- Sample Coating: The prepared surface was sputter-coated with Au/Pd using a Leica EM ACE600 ion sputter coater to improve conductivity and imaging quality in SEM.

- SEM & EDS: A CIQTEK 5000X FE-SEM combined with a Bruker XFlash 7 EDS detector was employed for high-resolution imaging and elemental analysis.

Automotive Paint Characterization Results and Discussion

Optical Microscopy of Automotive Paint Layers

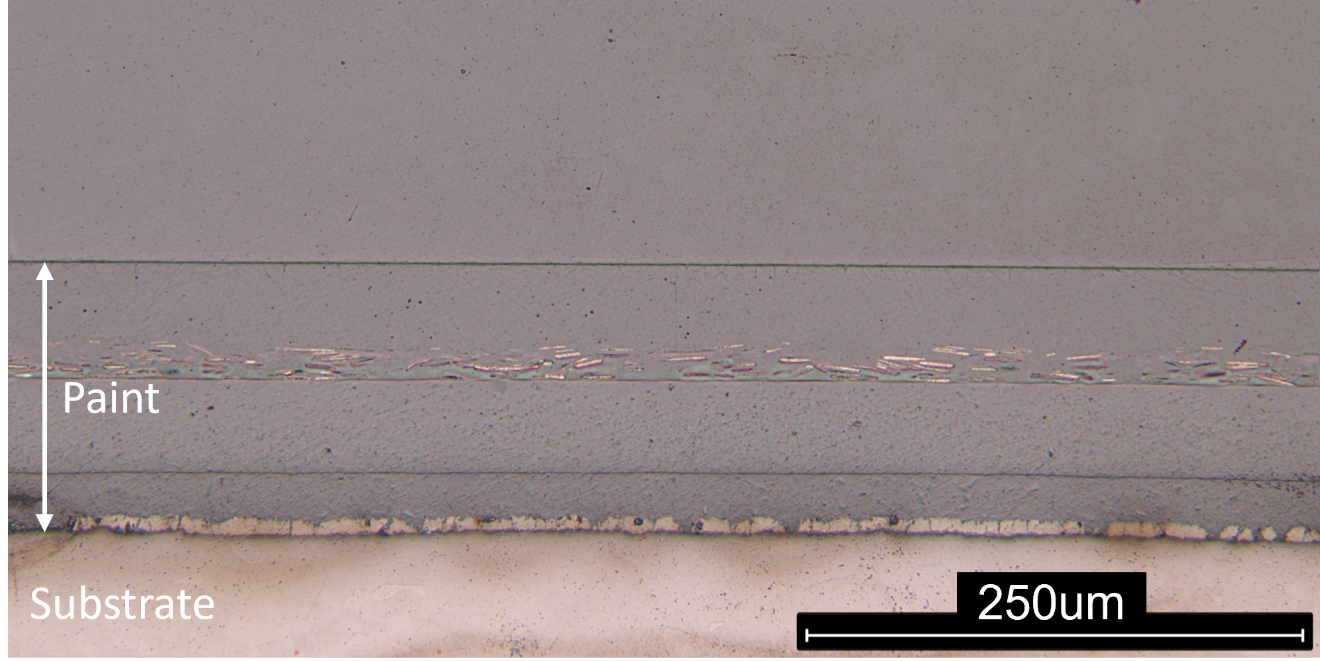

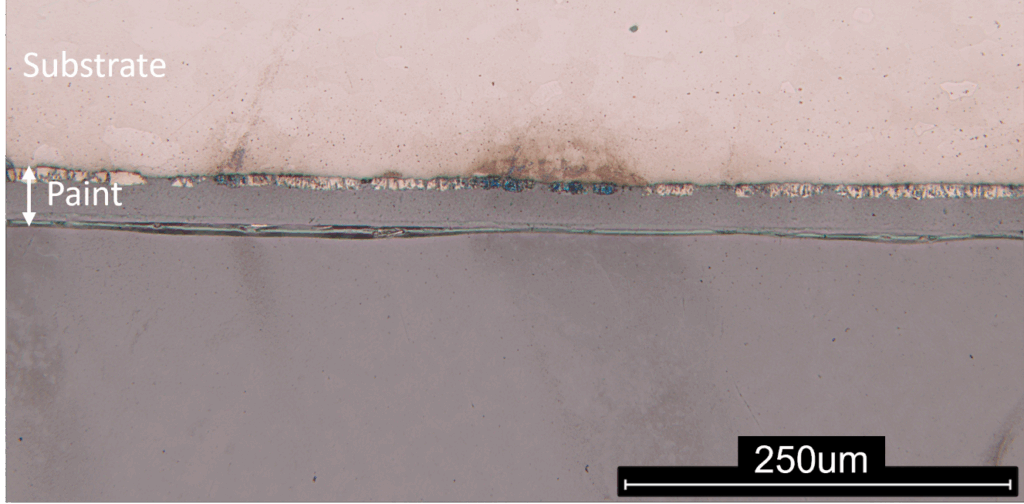

Optical microscopy provided an initial examination of the cross-section

Figure 1 shows the paint layers on both the outer and inner surfaces of the vehicle body.

(a) Outer surface

(b) Inner surface

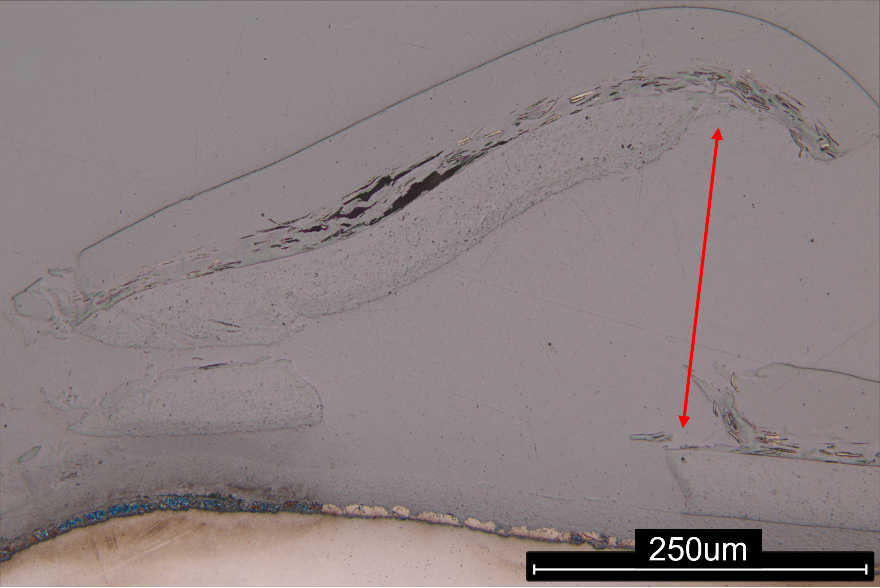

- Figure 2 reveals a region of delamination on the outer surface.

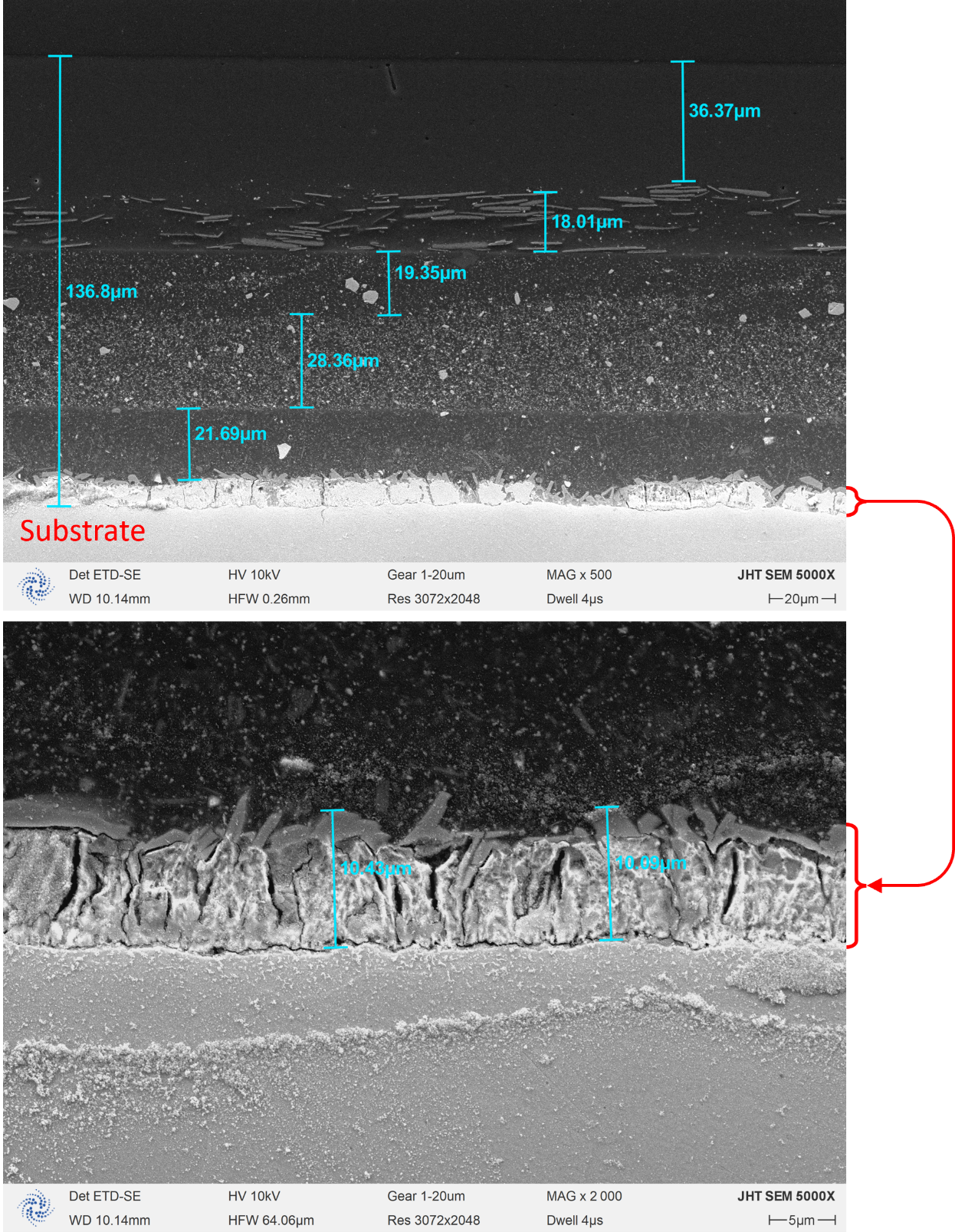

SEM Imaging and Paint Layer Thickness Analysis

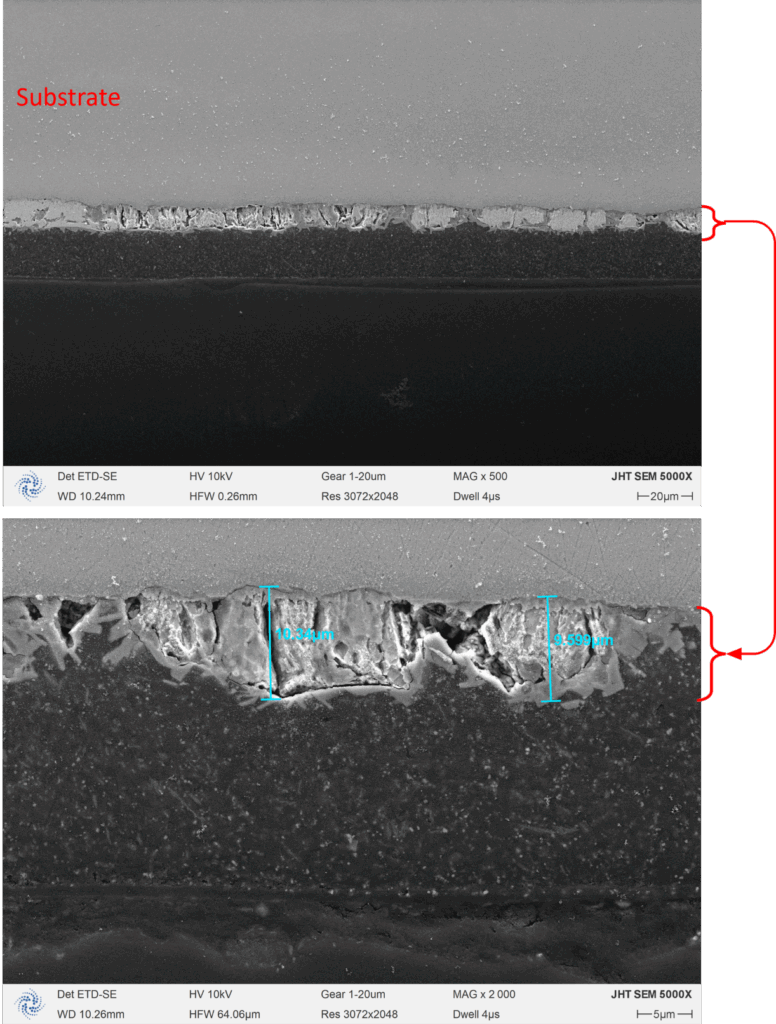

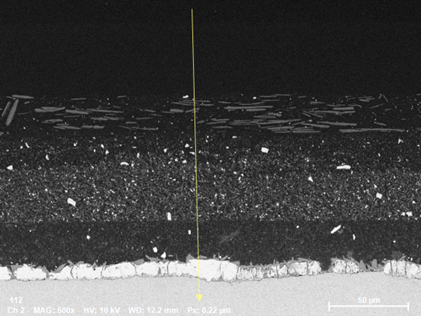

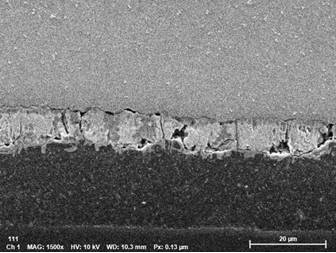

Secondary electron (SE) images of the cross-sectional layer structures for both the outer and inner surfaces are shown in Figures 3 and 4.

- Figure 3. The outer surface exhibits a complex multilayer structure with a total thickness of 136.38 µm. Individual layers (from the substrate outward) measure approximately 10 µm, 21.69 µm, 28.36 µm, 19.35 µm, 18.01 µm, and 36.37 µm.

- Figure 4. The inner surface shows fewer layers with simpler structures, all anchored to a ~10 µm primer layer directly on the substrate.

Elemental Composition of Automotive Paint

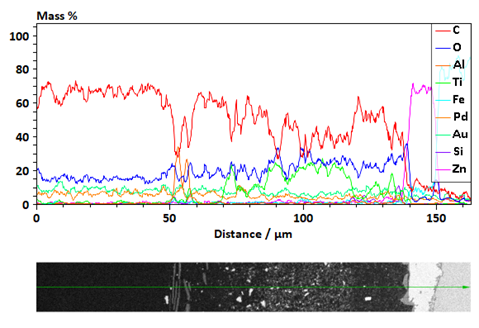

EDS measurement was applied to the outer and inner surface layer respectively.

Outer surface

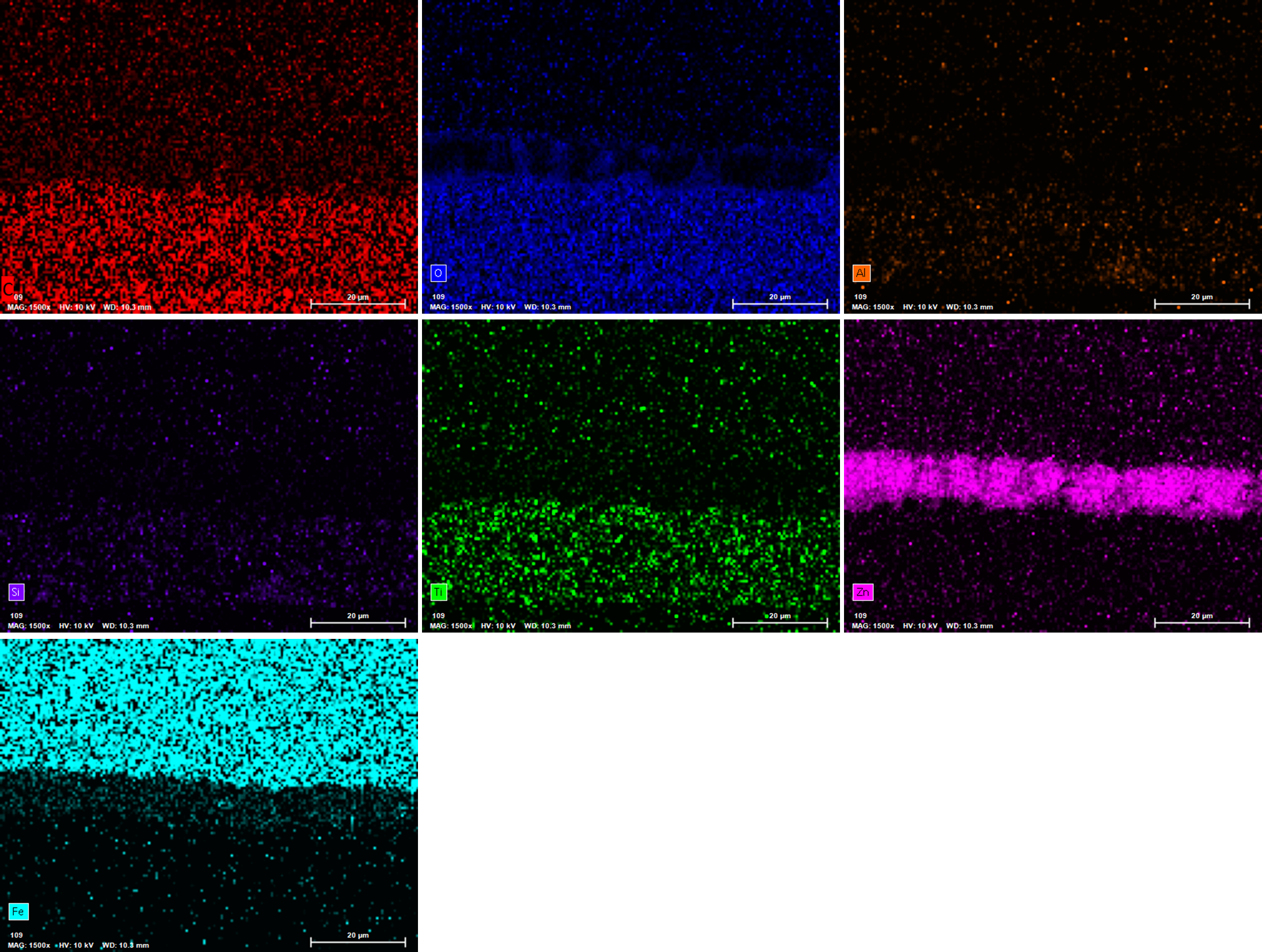

The EDS identified C, O, Al, Si, Ti, Fe and Zn. Figure 5 shows the SE image and distribution of Ti, Fe, Zn, Si and Al in the paint layers.

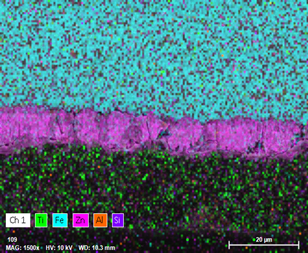

Inner surface

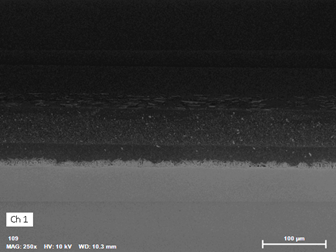

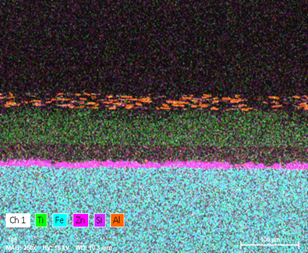

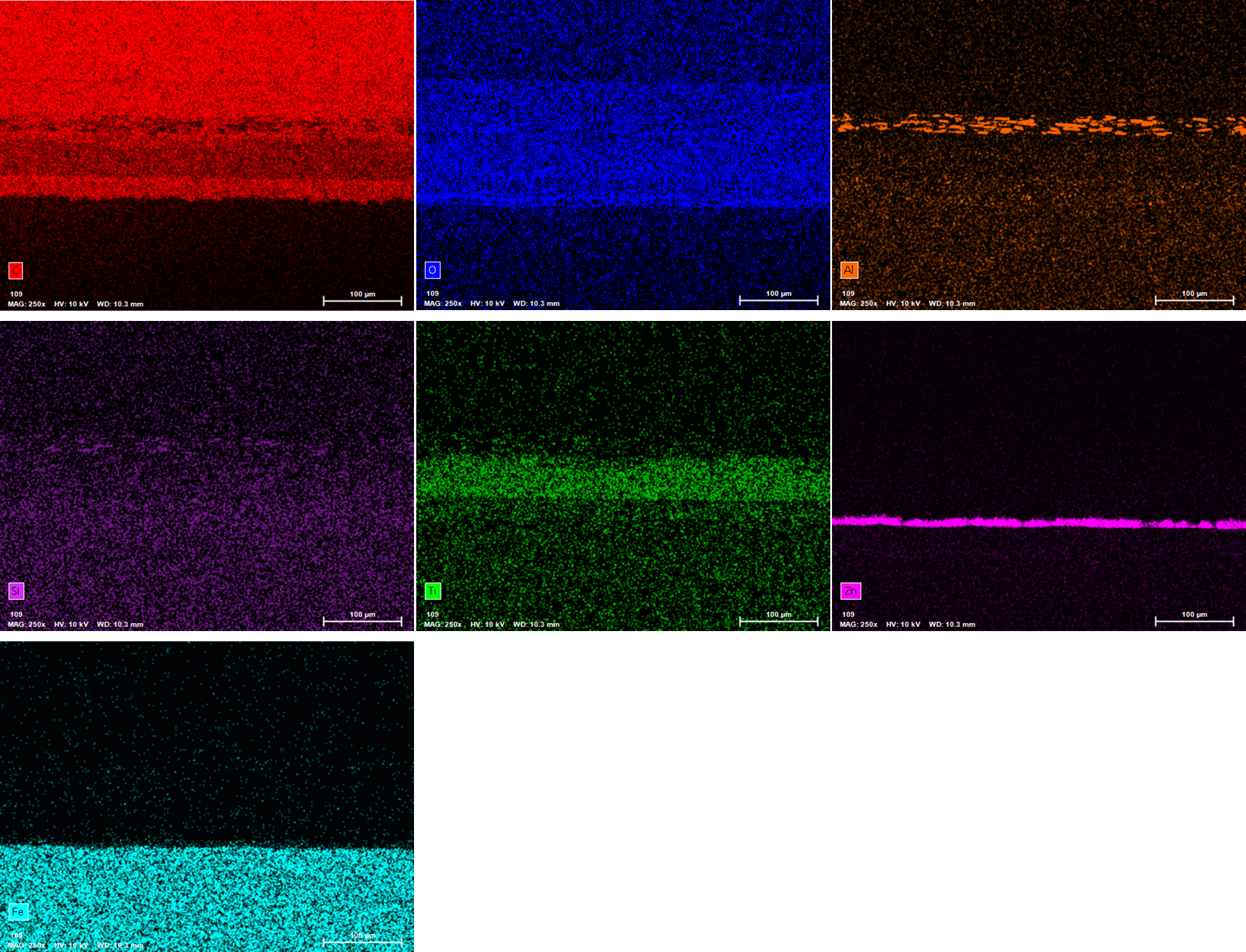

The EDS identified C, O, Al, Si, Ti, Zn and Fe in the inner side of the sample. Figure 8 and Figure 9 show the SE image and elemental distribution in the layers.

Conclusions

The multilayer architecture of automotive paint was confirmed using optical microscopy and SEM, with distinct differences observed between the inner and outer surfaces. EDS verified that the substrate is an iron-based car body, while the paint layers contain:

- C, O: From organic binders and resins.

- Al, Si: Associated with pigments, fillers, or extenders.

- Ti: From TiO₂ pigments for opacity and UV resistance.

- Zn: Indicative of anticorrosive primers.

These elements are commonly associated with specific functional components of automotive coatings, such as carbon and oxygen from organic binders, aluminum and silicon from fillers or pigments, titanium from TiO₂ pigments used for opacity and UV resistance, and zinc from anticorrosive layers. Layer-specific elemental distributions illustrate the functional design of each coating layer, contributing to corrosion protection, mechanical durability, and aesthetic properties.