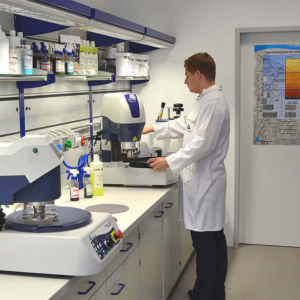

Sample Preparation

We understand the complexities involved in materials preparation and analysis. Our core strength lies in simplifying these intricate processes, allowing you to focus on your research or analysis goals without unnecessary complications. By providing user-friendly products and comprehensive support, we minimize the need for extensive training and reduce the risk of rework, saving you valuable time and resources.

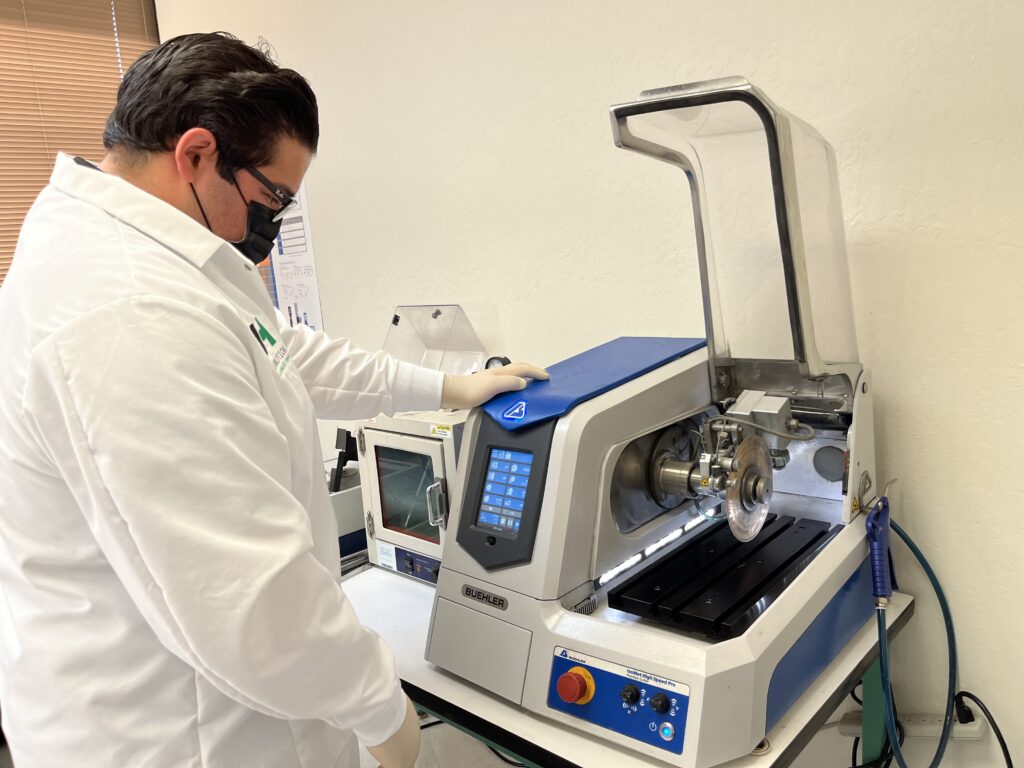

Achieving Precise Sample Preparation Starts with Cutting-Edge Sectioning Solutions

Buehler’s extensive selection of abrasive and precision sectioning saws serves as the foundation for successful sample preparation. Our advanced saws are designed to deliver clean, precise cuts, minimizing sample deformation and ensuring the integrity of your materials. Whether you’re working with metals, ceramics, composites, or geological specimens, our sectioning saws provide the accuracy and versatility you need.

Unlock Consistent and Reliable Results with Precise Sample Mounting Solutions

Achieving uniform sample shapes is key to ensuring consistency, edge retention, and sample flatness – essential factors that influence the quality of your results after grinding and polishing processes.

We understand the importance of precise sample mounting techniques. That’s why we offer a comprehensive range of hot and cold mounting options tailored to meet the diverse needs of materials analysis laboratories.

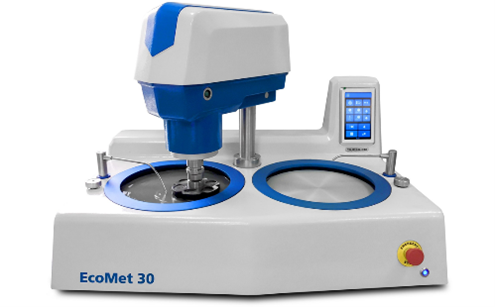

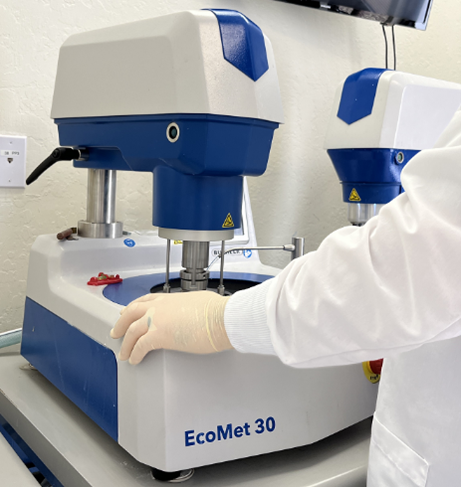

Achieve Superior Surface Finishes with Precision Grinding and Polishing Solutions

The grinding and polishing stage is paramount for obtaining accurate and reliable analysis results.

Our wide range of grinding and polishing equipment offers versatility and precision to accommodate a wide variety of sample types and applications. From manual to fully automatic systems, equipment is designed to deliver consistent and exceptional surface finishes, ensuring optimal preparation for your subsequent analysis techniques.

Features

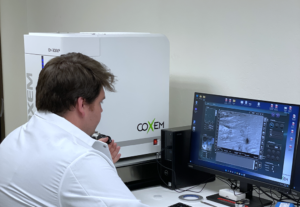

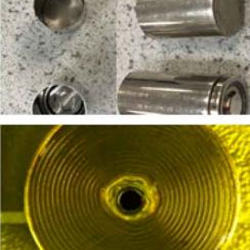

In addition to ion milling, we leverage advanced vibratory polishing techniques to achieve an unparalleled surface finish on your samples. This meticulous polishing process ensures optimal sample preparation, enabling you to capture intricate details and gather high-resolution SEM images with exceptional clarity at an affordable cost

At JH Technologies, we understand that successful materials characterization relies on a seamless workflow encompassing sample preparation, imaging, and analysis. What sets us apart is our unique approach – we don’t just provide the equipment; we actively utilize it in our own state-of-the-art laboratory. By offering sample preparation, imaging, and analysis services to our customers, we gain invaluable real-world experience, ensuring that our workflow solutions are tailored to meet the demands of your practical applications.