Coating Systems For Electron Microscopy

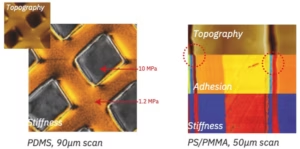

Electron microscopy coating systems deposit thin, conductive layers (e.g., gold, platinum, carbon) onto samples, preventing charging artifacts and enhancing contrast in SEM and TEM imaging. Common methods include sputter coating and thermal evaporation, with coating thickness typically 10-30 nm for SEM.

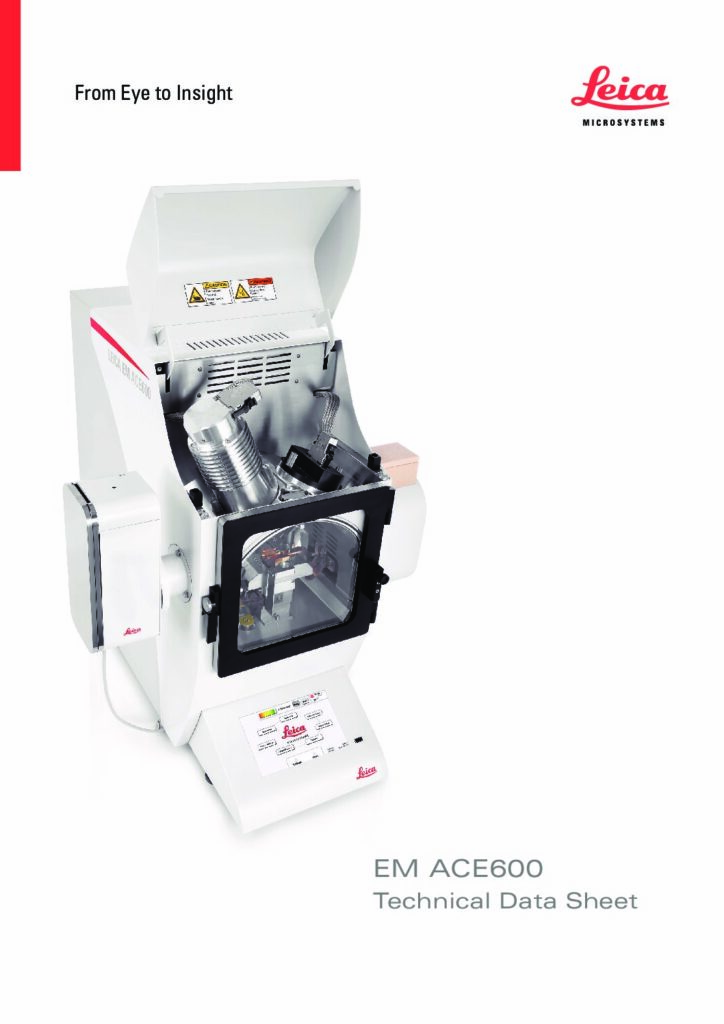

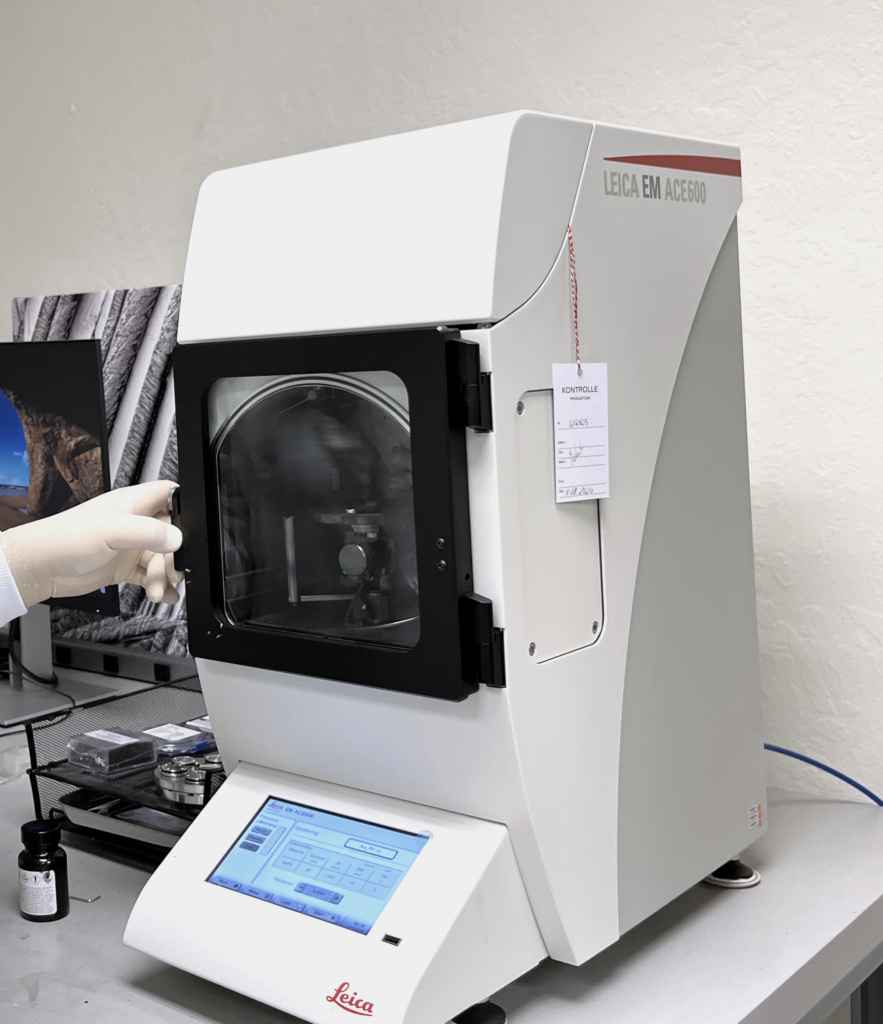

Leica EM ACE600 Sputter Coater

EM ACE600 sputter coater: a versatile, configurable chamber for diverse electron microscopy needs. Run dual sources or adapt for cryo-EM. Achieve high-quality SEM/TEM imaging with one flexible system.

- Perform high-resolution imaging of flat or structured non-conductive specimens

- Choose from robust carbon thread, e-beam, and sputter coater sources

- Enhance the contrast of nanometer-scale structures

- Provide protection layers for sensitive samples

- Uniform thickness, crucial for analytical investigations, quantitative imaging, or electron tomography

Leica EM ACE200 Low Vacuum Coater

The Leica EM ACE200 is a fully automated, high-quality desktop coater designed to produce homogenous coatings of conductive metal or carbon as needed for electron microscopy

- Quartz crystal measurement – for reproducible layers

- Planetary rotation – for even distribution of coating material on fissured samples

- Glow discharge – to make TEM grids hydrophilic

- Small footprint, fully automated, one-touch coating

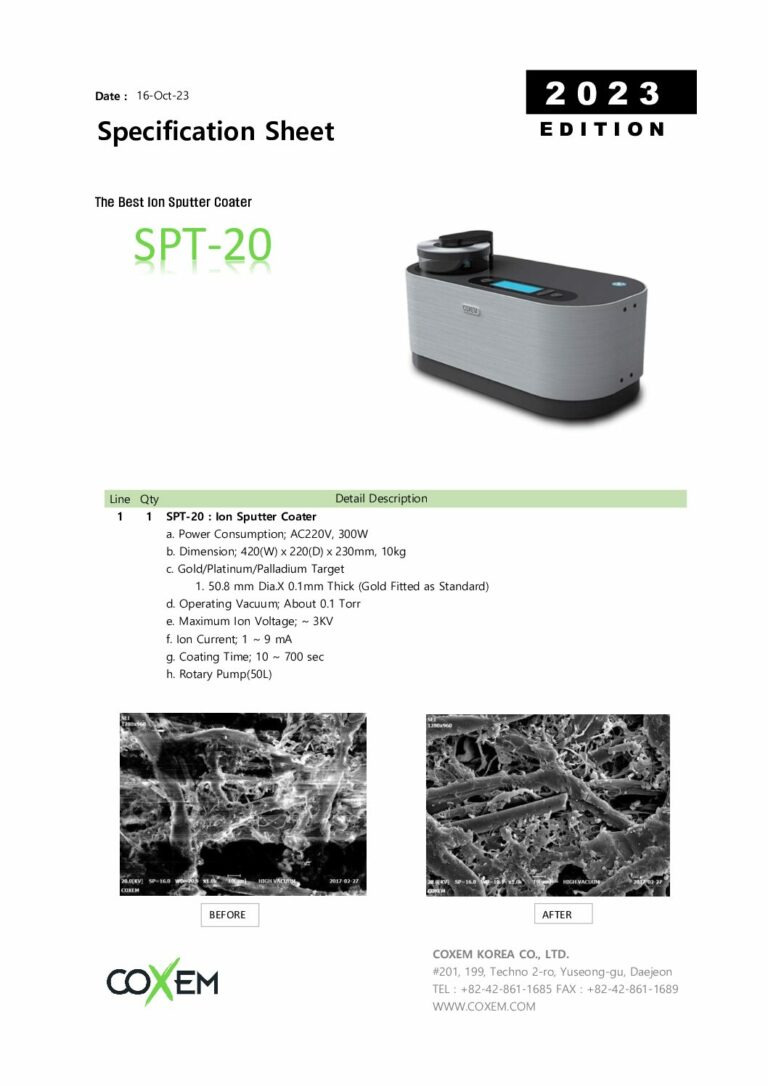

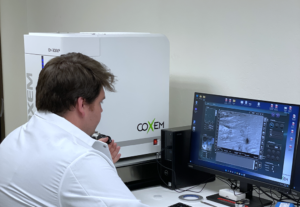

Coxem SPT-20 Ion Sputter Coater

Enhance your table-top SEM imaging with the SPT-20 Sputter Coater. This compact ion coating system deposits noble metals like gold, palladium, platinum, and silver onto non-conductive or poorly conductive samples. Ideal for improving conductivity and contrast in SEM imaging across materials science, biology, and more.

- Compact digital ion coater

- Stable coating with coating Current Feedback function

- Glow discharge – to make TEM grids hydrophilic

- Uses low-noise rotary pump