Microscope Cameras and Software

In the rapidly evolving world of microscopy, having the right tools is crucial for unlocking the full potential of your instruments. Our advanced microscope cameras and intuitive software solutions are designed to revolutionize your imaging and analysis workflows, empowering you to capture stunning visuals and extract valuable insights with unparalleled precision.

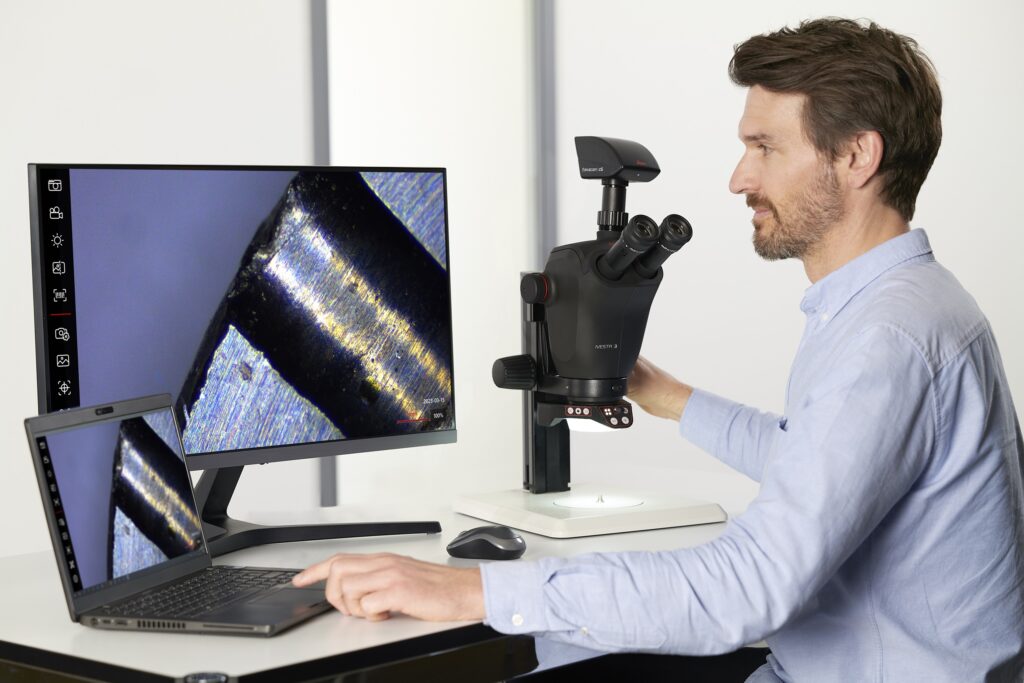

High-Performance Cameras for Viewing and Data Aquisition

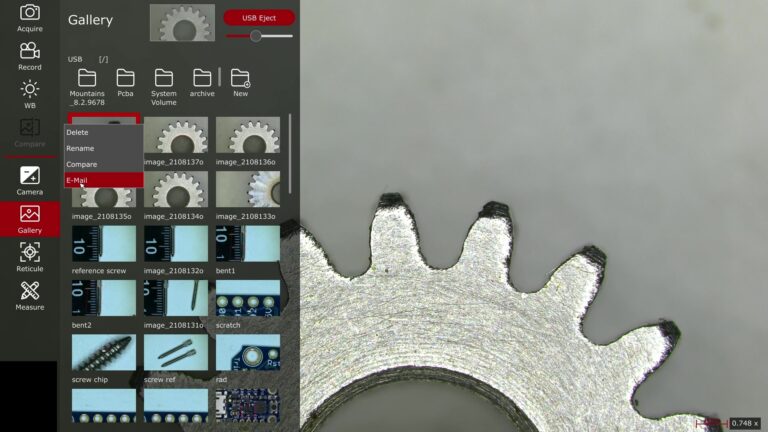

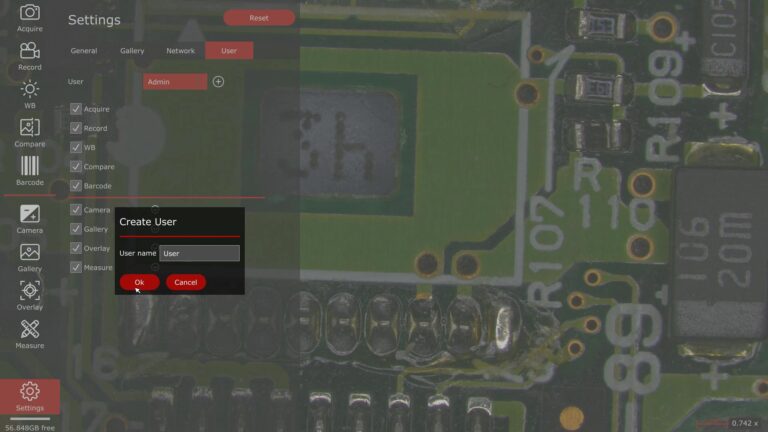

Flexacam microscope cameras offer precise color rendering and high resolution for viewing fine sample details. Combined with the intuitive Enersight software platform, they enable flexible viewing, documentation, and sharing of microscope images.

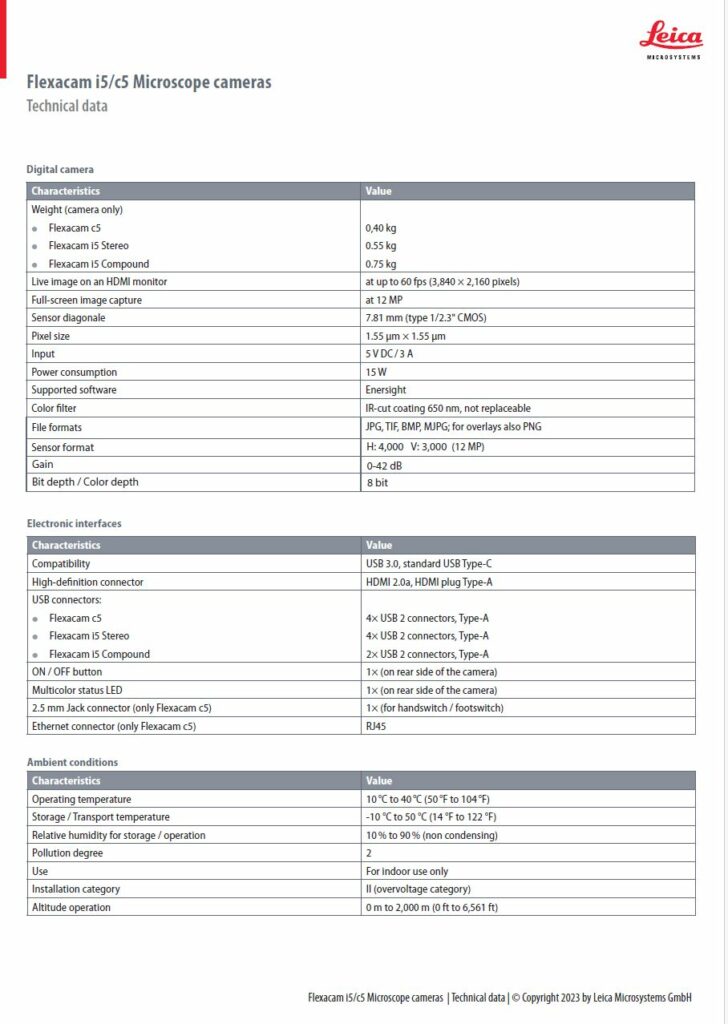

Technical specs translate to incredible live and captured images

The 12-megapixel CMOS sensor captures high-resolution images, revealing fine sample details. The fast auto exposure ensures clear differentiation between bright and dark samples, while the high 60 fps frame rate enables smooth visualization of sample movements.

Solutions for spectacular imaging and automated data collection

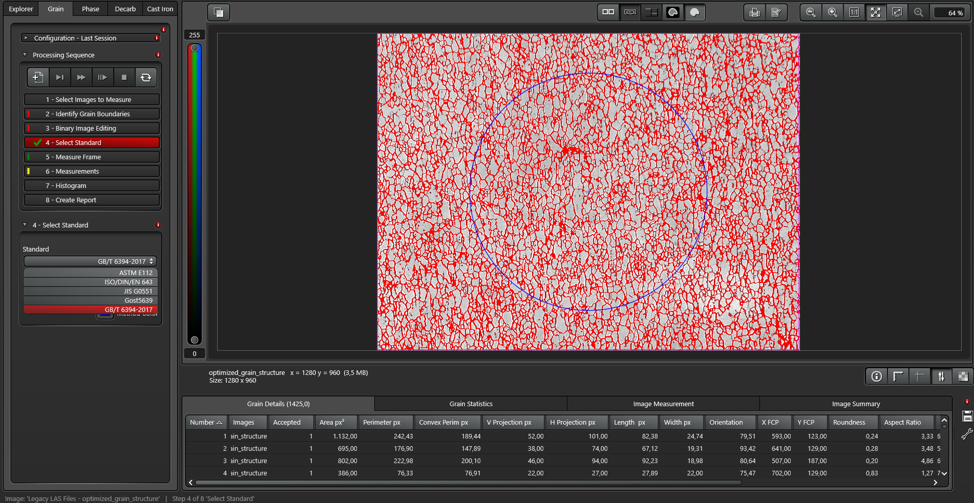

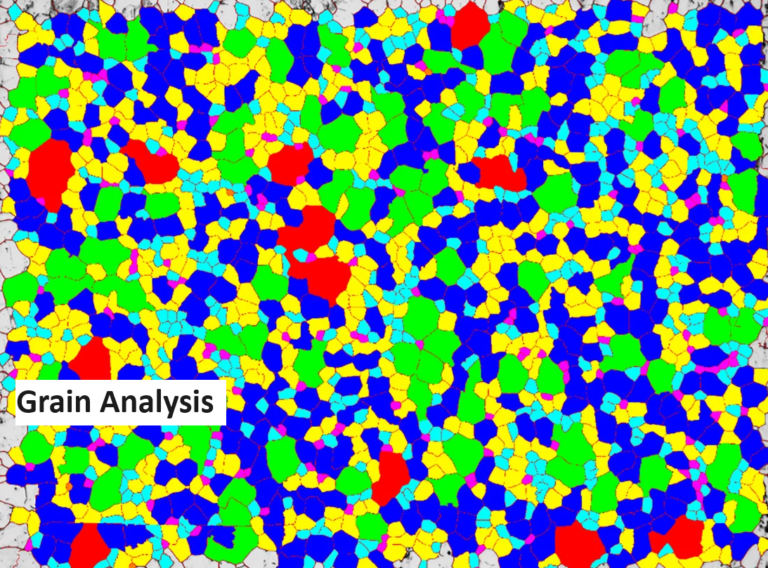

We offer user-friendly cameras for basic imaging requirements that seamlessly integrate with monitors, while our advanced systems cater to complex challenges across diverse industries, such as material analysis, earth science, steel inclusion detection, grain analysis, cleanliness testing, and more. Leveraging cutting-edge technologies like high-resolution microscopy, spectroscopy, and advanced image processing algorithms, our experienced professionals deliver tailored solutions that exceed expectations with accurate and reliable results.