Electron Microscopy Sample Preparation Systems

Preparing samples flawlessly is crucial for obtaining top-notch electron microscopy images. We understand the importance of meticulous EM sample preparation and offer preparation equipment

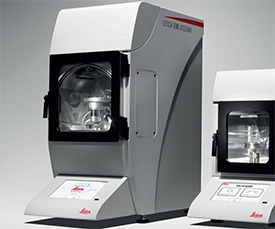

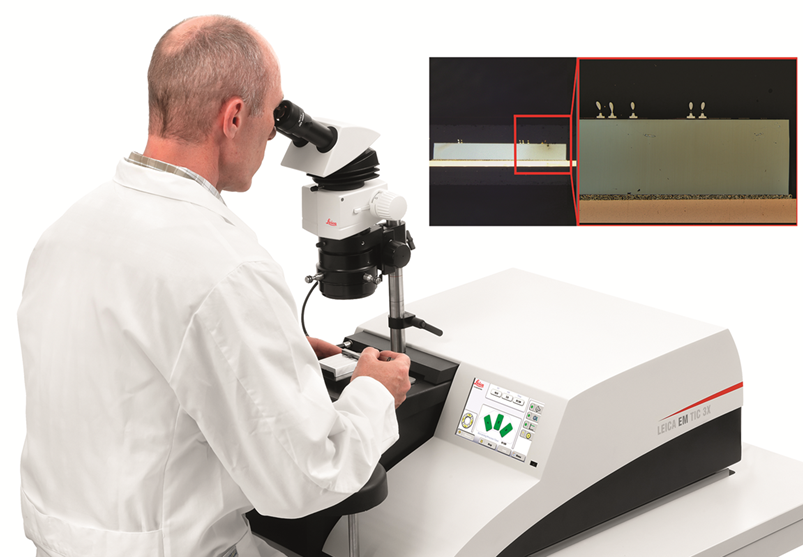

Ion Beam Milling Systems for EM Sample Prep

Ion beam milling is an advanced electron microscopy sample preparation technique used to eliminate surface damage and residual artifacts left behind by mechanical cutting and polishing. By precisely thinning and smoothing the sample surface without deformation, this non-destructive method is ideal for high-resolution electron microscopy imaging and accurate microstructural analysis.

Ion beam milling is essential for preparing samples for advanced techniques such as:

- Energy Dispersive X-ray Spectroscopy (EDS)

- Electron Backscatter Diffraction (EBSD)

- Wavelength Dispersive Spectroscopy (WDS)

- Auger Electron Spectroscopy (AES)

Sputter Coating Systems

Sample conductivity is critical for producing high-quality images in scanning electron microscopy (SEM). Non-conductive samples can develop surface charging, which degrades image resolution and contrast. To prevent this, a conductive coating is often applied to dissipate charge and stabilize the imaging process.

Sputter coating is a fast and effective method to apply an ultra-thin layer of conductive material —such as gold, platinum, or carbon—onto the sample surface. This enhances image clarity and ensures accurate analysis across a variety of SEM applications.