Recent Blogs

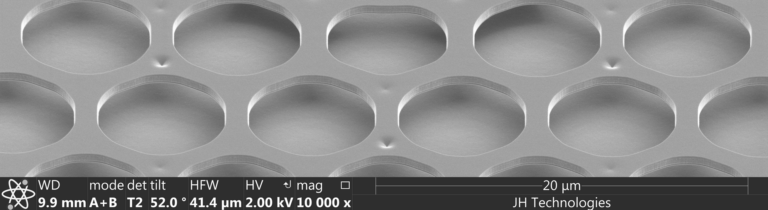

Precision Solder ball Analysis Using Ion Beam Polishing and SEM

Recent Blogs Precision Solder Ball Analysis Using Ion Beam Polishing

Tariff Policy Simplified: Stability, Transparency, and Trust

Recent Blogs JHT Tariff Policy: Stability, Transparency, and Trust Stability,

Demonstration Equipment: Beating The Tariff Trap

Recent Blogs Demonstration Equipment: Beating the Tariff trap In a

The Case of the Missing SEMs: A Story of Quick Thinking, Teamwork & Tech Recovery

Recent Blogs The Case of the Missing SEMs: A Story

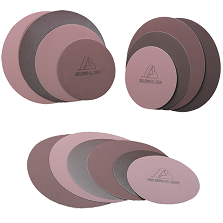

Sample Polishing Methods: Diamond Grinding Disks [APPLICATION NOTE]

When is it better to use Diamond Grinding Disks instead of Silicon Carbide Paper or Diamond Suspension?

People often ask us when they should use Buehler’s Diamond Grinding Disks (DGD) instead of other methods to grind and polish their samples. There are four different options available including DGD Color, DGD Ultra, Mosaic, and Terra. A fifth option is Apex Hercules which is used with diamond suspensions instead of polishing pads.

Most of the time we suggest different polishing methods based on the specific application, but one big reason to consider using DGD’s is to reduce waste, sending less material to landfills. A single DGD can replace up to a box of SiC paper producing much less waste.

A second reason DGD’s are favored is to save time and steps in automated systems. DGD’s reduce replacement of SiC paper every few minutes, especially with harder materials. This allows you to run the process without interruption for SiC paper replacement saving valuable processing time.

Some specific details of each diamond grinding disk and in order of appearance in the Buehler catalog:

Some specific details of each diamond grinding disk and in order of appearance in the Buehler catalog:

DGD Mosaic

We recommend DGD Mosaic for all ferrous metals, but it is best suited for harder metals like Tool Steel. The coarsest grits will allow for very fast material removal while maintaining excellent flatness. For softer metals or shorter processes use DGD Color (SiC paper may work just as well). Mosaic is available from 125um to 10um grit (120 grit to 1000 SiC grit comparable)

DGD Color

DGD Color works well on softer alloys (although it can be used on harder ones too with extended processing time) and is well suited for softer metals like aluminum, brass and copper. You can combine DGD Color with polishing cloths and diamond suspension in a process by using the DGD Color for the coarser grinds and then change to 3um or 1um diamond suspension for final polish. DGD Color is available from 240um to 8um grits.

DGD Ultra

DGD Ultra is the disc for very hard materials and ceramics (Tungsten Carbide, Boron Carbide, Silicon Nitride, etc. ). The DGD Ultra uses a Nickel bond instead of resin which makes it more durable for the higher pressure, longer time, grinding processes. It is the most durable of all the DGD’s. Use it where you find you are tearing SiC paper or losing flatness due to the hardness of your material. Combine with diamond suspensions and pads for a final finish. Ultra is available from 125um to 6um grit.

DGD Terra

DGD Terra use is mostly for minerals, TSC, glass, everyday brittle ceramic (alumina, ceria and anything unfired). Terra is available from 165um down to 0.5um grit.

Apex Hercules

Apex Hercules is not a diamond grinding disk, but provides a resin surface which is used in combination with diamond suspension. It grinds with less friction than other abrasive materials, so it provides a very flat surface finish in. Like polishing pads, Hercules must be kept wet with suspension to prevent premature wear and damage to your samples.

Need assistance with your analytical lab application? Complete the form on this page or give us a call at (408) 436-6336.