Hardness Testing Solutions - Testers, Blocks, and Software

We understand the importance of reliable hardness testing for quality control and material characterization. That’s why we offer complete hardness testing solutions that combine state-of-the-art testers, certified test blocks, and intuitive software designed specifically for hardness testing.

Accuracy and Reliable Performance

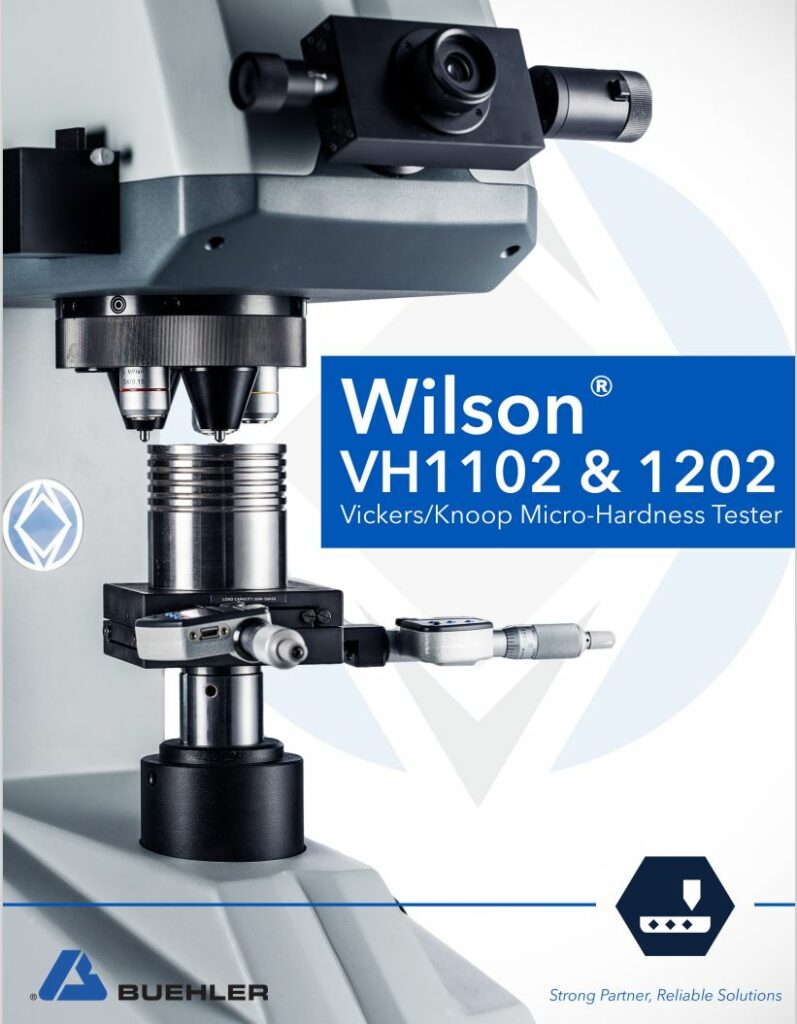

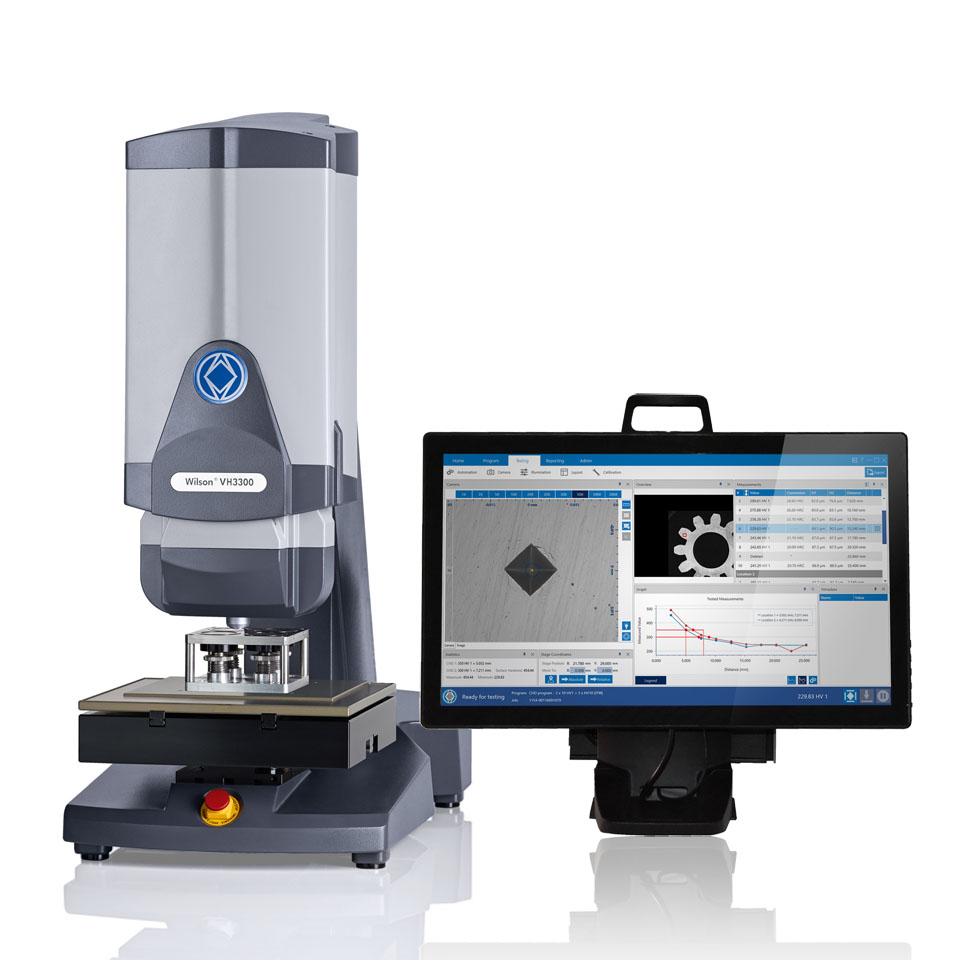

Buehler’s hardness testers are renowned for their accuracy, durability, and ease of use. Whether you require Vickers, Knoop, Brinell, or Rockwell hardness testing, our testers deliver precise measurements and reliable performance.

Consistent And Reproducibility

Our hardness testing systems are engineered to work seamlessly together, eliminating ambiguity and ensuring consistent, reproducible results. From user-friendly interfaces to advanced software capabilities, our solutions are designed to streamline your hardness testing workflow.

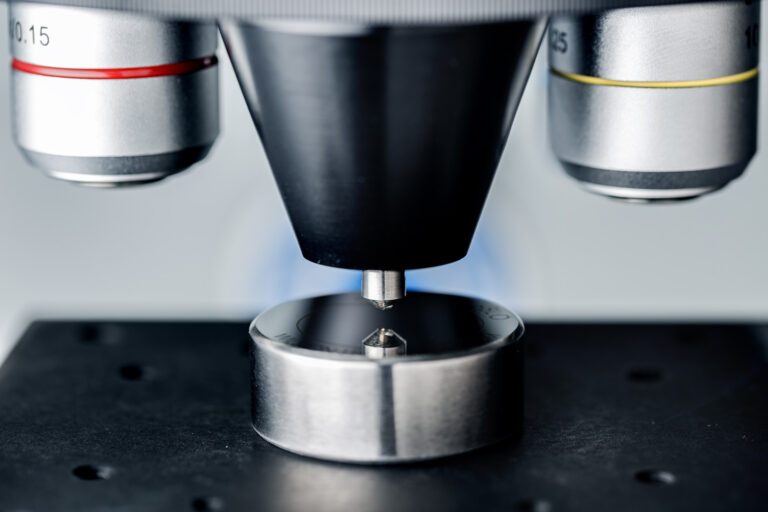

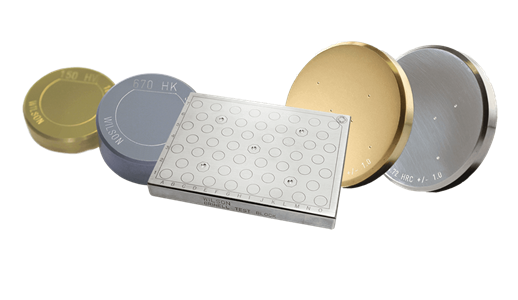

Hardness Test Blocks

Hardness test blocks for various testing methods including Vickers Knopp, Brinell, and Rockwell.

Features

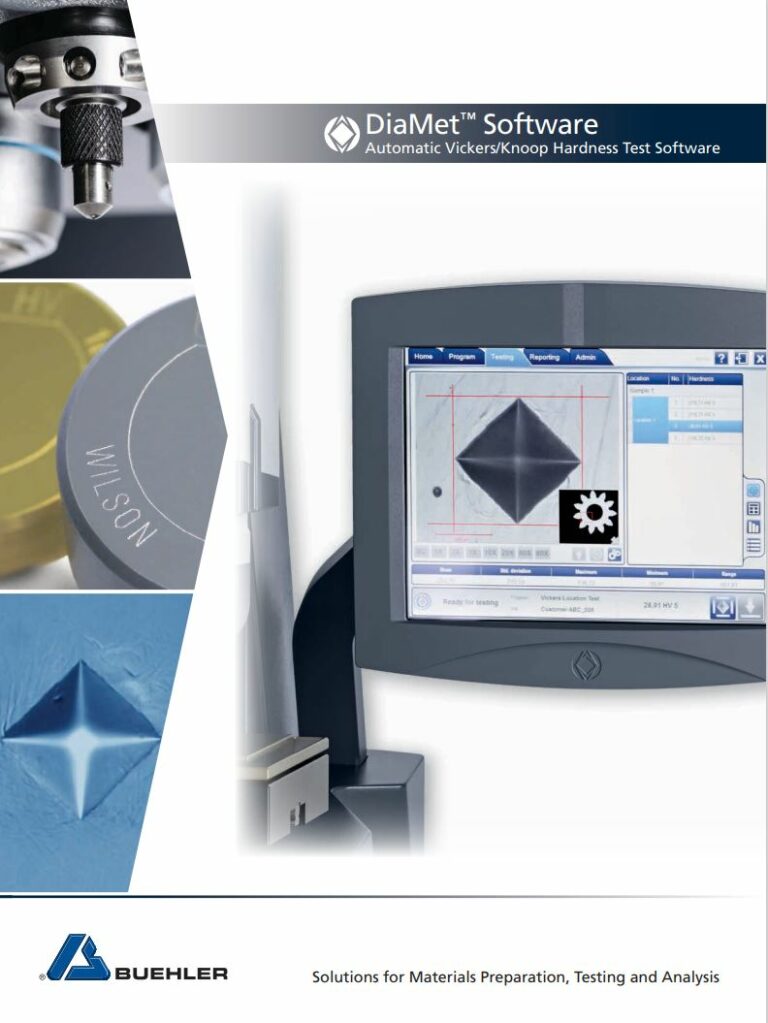

DiaMet Hardness Testing Software is designed to revolutionize your hardness testing workflow, offering seamless automation and user-friendly controls tailored to your specific application needs. With its comprehensive suite of features, DiaMet ensures efficient and accurate hardness testing, minimizing operator involvement while maximizing productivity.