Metallography Equipment for Sample Preparation

We understand the complexities involved in materials preparation and analysis. Our core strength lies in simplifying these intricate processes, allowing you to focus on your research or analysis goals without unnecessary complications. By providing user-friendly products and comprehensive support, we minimize the need for extensive training and reduce the risk of rework, saving you valuable time and resources.

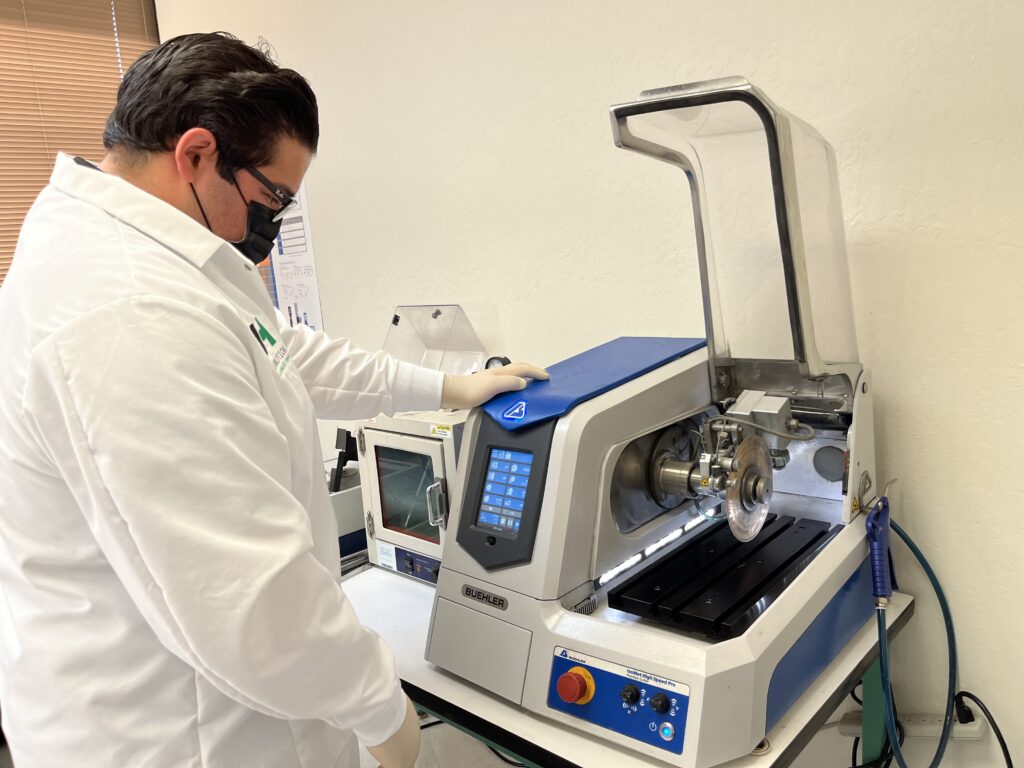

Metallographic Sectioning Equipment

Sectioning is the first and one of the most critical steps in metallographic sample preparation. A clean, controlled cut preserves the structural integrity of your sample, minimizing deformation, cracking, and heat-affected zones that can compromise later analysis.

Abrasive cutting is often used for large or hard materials, while precision sectioning is ideal for delicate or small-format samples. The right metallographic cutting machine depends on your sample size, material hardness, and required throughput.

Metallographic Mounting Equipment

Mounting is another critical step in metallographic sample preparation, serving both to protect delicate samples and to standardize their shape for grinding and polishing. A well-mounted sample helps ensure flatness, edge retention, and structural integrity— factors that directly influence the microstructural analysis accuracy.

There are two types of mounting techniques: hot mounting, which uses heat and pressure to cure thermosetting resins, and cold mounting, which involves chemically curing resins at room temperature. Choosing the right method depends on the material type, sample size, and lab throughput needs.

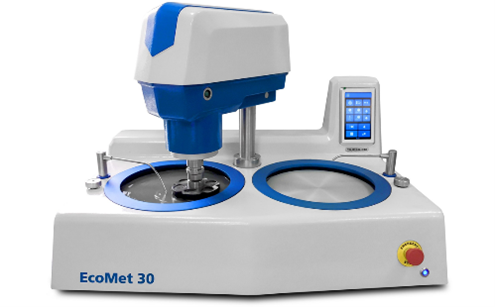

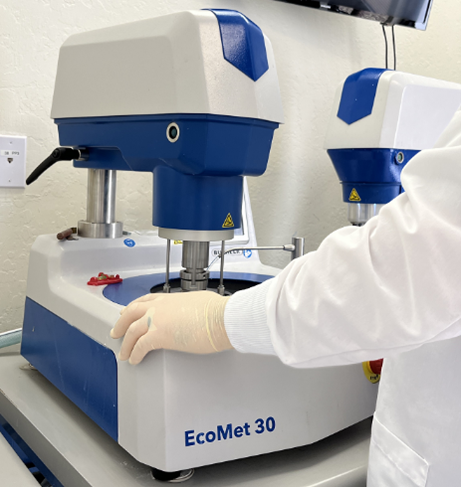

Metallographic Grinding and Polishing Equipment

After sectioning and mounting, grinding and polishing is the final critical stage in metallographic sample preparation. This process removes surface damage and reveals the microstructure needed for accurate optical or electron microscopy analysis.

Proper grinding ensures a flat surface free from scratches and embedded debris, while polishing refines the surface to a mirror-like finish that enhances contrast and clarity. The choice between manual and automated systems depends on your lab’s throughput, level of precision, and operator experience.

Metallography Sample Prep Product Models

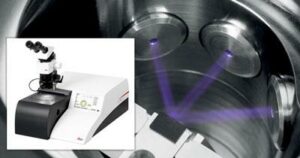

In addition to ion milling, we leverage advanced vibratory polishing techniques to achieve an unparalleled surface finish on your samples. This meticulous polishing process ensures optimal sample preparation, enabling you to capture intricate details and gather high-resolution SEM images with exceptional clarity at an affordable cost